Anticipated Lead Times. In addition to an accurate demand forecast, you also need to anticipate the lead time for inventory replenishment. Consider these four elements:

- Time required to place an order

- Time taken for order processing and shipment

- Timeframe till delivery to your warehouse

- Preparation time for use/sale of stock receipt

The accuracy of anticipated lead times also needs to be established. Use a report that checks these elements of a stock receipt:

- Whether the lead time is 50% higher than anticipated

- Whether the lead time is 50% lower than anticipated

- Whether lead time is more than seven days late/early

Sharing this information with vendors helps you ensure that future replenishment orders are placed in time. Check with them if future lead times will be the same or if they were caused by one-time factors. If they continue to be inconsistent, you may need to look for other reliable vendors.

Safety Stock. Even with accurate demand forecasts, maintaining a safety stock or extra inventory is a good idea. The more accurate your future demand predictions and anticipated lead time are, the less safety stock you will need to maintain. Still, replenishment orders may arrive late, or you may sell more than you anticipated.

It’s also essential to weigh final products accurately before packaging, using automated weighing and packaging scales. Here’s why:

- Production becomes more scalable, dependable and reliable

- Weighing and packaging processes become faster and simpler

- Shipping costs and packaging expenses are minimized

- Final product packaging is more refined, consistent and uniform

- Accurate product weight and size is maintained according to FDA regulations

- Safety is improved and health risks are significantly reduced

- Warehousing, shipping and delivery become more convenient

- Tracking lost/damaged materials becomes easier

FSMA and Stricter Regulations for the Food Industry

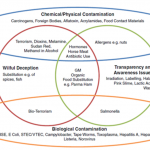

FSMA gave the FDA more authority to regulate the growing, harvesting and processing of food. Today, the FDA requires comprehensive, preventive-based controls across the food supply chain. It also issues regulations to protect against deliberate contamination, preparing and protecting the food supply chain at specific vulnerable points with preventive strategies.

Stricter regulations for food manufacturing and supply only add to the worries of supply chain managers, making cooperation between manufacturers, vendors and customers even more critical. It may just be time for companies involved in food manufacturing and processing need to look at SCM best practices a little more seriously.

A major selling point of food is its’ quality – and food safety training is key to that quality.

• Businesses are more likely to hire food safety trained handlers and are willing to pay higher wages to those trained.

• Keep current with Food Safety standards and regulations!

• Food Manager ANSI Certification – On SALE $99.00 – Valid in all States and for 5 years.

• Food Handler ANSI Training for only $7.00!

• Visit Food Handler University: http://foodhandleru.com

10% OFF SALE: Enter Promo “TRAIN10OFF” at Checkout