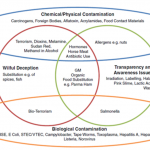

While building an effective logistics strategy, the end goal of supply chain management (SCM) needs to be kept in mind (i.e., allowing each member of the supply chain to achieve efficient inventory management as well as reach its customer service goals). To this end, it’s important to share information that will help each member achieve success. This includes data relating to demand forecasts, anticipated lead times and safety stock quantities. Let’s look at SCM best practices for food manufacturing and supply, and how this information plays a role.

Effective SCM: Best Practices for the Food Industry

Here’s an overview of SCM best practices in food supply and manufacturing:

Learn more about managing your supply chain at the Best Practices in Food Safety Supply Chain conference | June 5–6, 2017 | LEARN MOREDemand Forecasts. This is generally based on demand, sales or usage patterns in the past. However, future demand can be affected by changing situations such as:

- Gaining/losing customers

- Increased/decreased product popularity

- Introduction of new products

- Short-term increase in demand through promotions, etc.

Better estimates can be achieved with an effective derived demand or a CPFR (collaborative planning, forecasting and replenishment) system. This can be done through automated data collection, or by the following process:

- Identifying customers who can predict future demand (i.e., what they may use or sell in the future)

- Collecting demand forecasts about specific products from them

- Comparing these forecasts against their actual purchases on a monthly basis

- Helping them improve future predictions by sharing this data with them

Customers may overestimate demand, but you might consider offering a discount based on accurate forecasts to encourage better results. In addition, you should also consider these five elements:

- Usage patterns in the past, not including CPFR data

- Increasing/decreasing product popularity trends

- Higher/lower seasonal usage or demand

- Events/promotions in the near future

- Market and industry data from sources such as management, sales, etc.

A major selling point of food is its’ quality – and food safety training is key to that quality.

• Businesses are more likely to hire food safety trained handlers and are willing to pay higher wages to those trained.

• Keep current with Food Safety standards and regulations!

• Food Manager ANSI Certification – On SALE $99.00 – Valid in all States and for 5 years.

• Food Handler ANSI Training for only $7.00!

• Visit Food Handler University: http://foodhandleru.com

10% OFF SALE: Enter Promo “TRAIN10OFF” at Checkout