Fast Facts about Biofilm

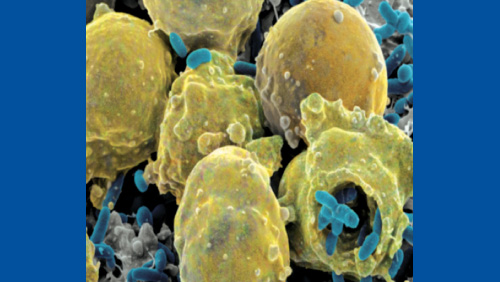

It hides in the crevices. Once it gets onto equipment, it can linger for years. It’s biofilm, a formation of bacteria that adheres to surfaces and can be quite difficult to eradicate. A host of microorganisms, including Listeria and Salmonella, are linked to biofilm contamination. The following are insights gathered from Dominique Blackman, general manager at Realzyme, LLC and Jeff Mitchell, vice president of food safety at Chemstar during Food Safety Tech’s recent Listeria Detection & Control Workshop.

Biofilm Facts

- Protected by multiple layers of polysaccharides

- Acts as binding site for antimicrobials as well as a diffusion site, protecting bacteria within

- Mechanisms of dispersal

- Active: Releases cells based on environmental changes

- Passive: Occurs as a result of shear or agitation (i.e., when doing deep cleans or moving equipment)

- Hot spots

- Transfer points in facility

- Product contact points on equipment

- Drains

- Seams in walls/floor-wall junctures

- Door seals

- Cart wheels

- Overhead vents and pipes

- Causes a variety of problems within food manufacturing facilities, including:

- Product contamination = Economic loss (i.e., as a result of recalls)

- Reduced product shelf life (i.e., result of recurring contamination)

- Reduced productivity, especially when equipment isn’t cleaned properly

- Bacterial resistance to disinfection

- Surface corrosion (the longer biofilm is in one place, the more time it has to damage equipment)

- Successful removal requires complete penetration of extracellular polymeric substance without inactivating any sanitizer