Integrated Informatics: Optimizing Food Quality and Safety by Building Regulatory Compliance into the Supply Chain

Global food supply chains offer consumers more choice than ever before. Thanks to international networks of producers, wholesalers, manufacturers and suppliers, many ingredients can be sourced all year round, meaning diets are no longer limited by what’s in season. However, the increasing complexity of these supply chains means many food and beverage products are potentially more exposed to biological and chemical contamination as well as food fraud issues, putting brand reputation and human health at risk.

With consumer trust and public safety of paramount importance, global food regulators have introduced strict rules to protect the quality and authenticity of products. Regulations such as the FDA’s Food Protection Plan, for example, seek to incorporate safety measures throughout food supply chains in order to better prevent and respond to potential issues.1 These regulations are complemented by standards such as the ISO’s recently updated ISO 22000:2018 guidelines that recommend the implementation of hazard analysis and critical control points (HACCP) to achieve the highest levels of quality control (QC).2 For businesses working within this regulatory framework, it is essential to take a coordinated approach to deliver the standards of food quality and safety that customers and regulators expect.

Every food supply chain will have its own set of product specifications and QC parameters. However, all these requirements demand that decisions on the release of goods are made using accurate and timely information. Given the growing attention from regulators on the safety and provenance of food, as well as the need for operations to run as efficiently as possible, supply chain stakeholders are reevaluating the digital platforms they use to manage, store and recall their data. Here, we consider how laboratory information management systems (LIMS) can help businesses integrate efficient data collection workflows across multiple locations to support robust QC testing and build regulatory compliance into their operations.

Meeting the Challenges Facing Modern Food Supply Chains

Assuring consistent product quality and safety is a constant challenge for food supply chain businesses, given the broad range of issues that can compromise these standards. Although most businesses adopt strict storage and handling protocols to minimize the risk of foodborne illnesses caused by bacterial contamination, high-profile public health stories regularly hit the headlines. The widespread use of pesticides and veterinary drugs in farming also means that ingredients are potentially exposed to a wide range of known and unknown chemical contaminants. Contamination can also occur during the handling, processing and packaging stages. Robust QC measures are therefore essential to identify issues as early as possible.

Equally, food adulteration and counterfeiting continue to be key challenges, with high-value products regularly targeted by food fraudsters. The Grocery Manufacturers Association estimates that up to 10% of all commercially sold food products are affected by these practices, costing the industry between $10 and $15 billion each year and putting public health at risk.3 Comprehensive QC testing, supported by robust chain of custody data, is required to demonstrate quality and authenticity of goods, protect brands and safeguard consumers.

However, the extended nature of modern food supply chains can make delivering against these goals more difficult, especially if poorly integrated information management approaches are employed. As food supply chains have gone global, it has become increasingly common for businesses to operate storage, production and processing facilities across sites in multiple regions, countries and even continents. To deliver goods that meet well-defined safety and quality specifications, QC workflows must be built upon standardized protocols that are implemented correctly across the supply chain, regardless of the individual following them or the location in which they operate. These workflows must be supported by robust information exchange mechanisms that make sure the right decisions around product manufacturing and batch release can be made using accurate, complete and up-to-date information.

Improving QC Data Quality Using Integrated Data Management Solutions

With fragmented information management approaches often getting in the way of this ideal, many food businesses are looking to transform their poorly connected systems into informatics platforms that streamline operations, improve visibility and reduce errors. The latest LIMS allow businesses to bring all their QC data into a single integrated system, helping to harmonize processes and make information sharing more efficient to enhance product quality and safety.

Take the execution of standard operating procedures (SOPs) for pesticide residue testing, for example. By centrally connecting instruments and storing SOPs digitally on a LIMS, processes and parameters can be downloaded directly, eliminating the need for human error-prone manual set-up and supporting the consistent collection of data. Furthermore, because these SOPs are located in a centralized system, securely accessible to authorized users across all sites and facilities, the risk of SOPs becoming out of date or out of sync is greatly reduced. With guidance on residue levels regularly updated to reflect the evolving knowledge of these threats, ensuring the latest testing protocols are applied is particularly important.

Additionally, because LIMS capture and store QC measurements directly, as it is generated, they eliminate the need for labor-intensive transcription and data transfer processes. Not only does this improve measurement accuracy by taking human error out of the equation, it also boosts efficiency and reduces the administrative burden on those responsible for collecting QC data. As a result, experienced staff can spend less time on paperwork and data entry, and more time actively optimizing processes and finding solutions to other key challenges. With access to the most accurate and up-to-date information, businesses are better placed to maintain the integrity of the food supply chain and can act to resolve potential issues before they turn into more significant problems.

Supporting Well-Defined QC Processes and Regulatory Compliance

With international food regulators turning their attention to the methods used to assure the quality and authenticity of foodstuffs, supply chain stakeholders are now expected to have well-defined QC workflows that not only provide complete traceability of products from farm to fork, but also transparency around processes such as instrument calibration and data handling.

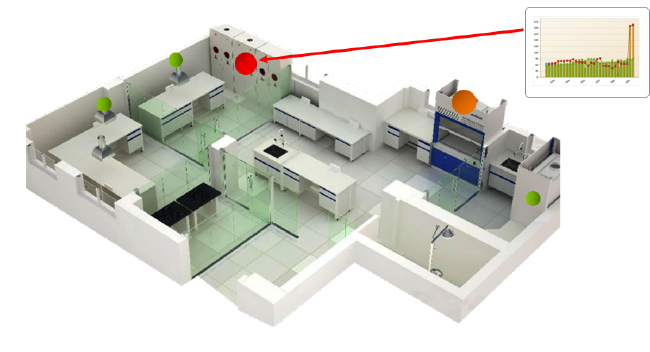

LIMS allow food businesses to build regulatory compliance into their processes by providing a comprehensive overview of all supply chain data, including information associated with QC steps. As all data required to support proof of compliance is organized in a single system, it can be quickly and conveniently recalled for sharing or review purposes. Some of the latest systems allow users to visualize this data holistically on process diagrams or dashboards, helping to fulfill HACCP requirements and make keeping track of active workflows as easy as possible.

Furthermore, because LIMS can be used to capture and store data automatically, they also facilitate the real-time monitoring of supply chain processes, meaning out-of-specification QC parameters can be flagged and reported earlier. The sophisticated algorithms present in some of the latest LIMS can even be used to warn businesses of small but significant trends such as the decline in performance of an aging instrument, which could cause unexpected downtime or cause product quality standards to fall over time. These alerting capabilities mean potential issues can be remedied faster, helping stakeholders more proactively protect consumer safety.

Defensible data is central to protecting brand integrity, especially when it comes to issues around food adulteration and counterfeiting. As such, food businesses need robust data management tools that support complete traceability of actions. By automatically recording every interaction with the system to generate a comprehensive audit trail and facilitating the use of e-signatures to document review procedures, LIMS can safeguard the highest levels of accountability, from data collection all the way through to results reporting. Some of the most advanced LIMS also feature powerful audit trail search functionality, allowing authorized users to recall specific actions such as unusual QC activity or potentially non-compliant behavior. With a secure record of events and a single, integrated platform for supply chain data, food businesses can focus on what’s important—optimizing processes and delivering high-quality goods.

Optimizing and Safeguarding the Food Supply Chain Using LIMS

Modern LIMS allow food supply chain stakeholders to build regulatory compliance into their workflows by standardizing QC processes and giving authorized individuals full visibility over their data. By facilitating faster and more informed decision-making using accurate and up-to-the-minute data, LIMS are helping businesses meet current industry challenges head on to maintain the safety and integrity of the food supply chain.

References

- FDA. (November 2007). Food Protection Plan. Access April 7, 2019. Retrieved from , https://www.fda.gov/downloads/aboutfda/centeroffices/oc/officeofoperations/ucm121761.pdf .

- International Organization for Standardization. (June 2018). ISO 22000:2018(en) Food safety management systems — Requirements for any organization in the food chain..

- The Grocery Manufacturers Association and A.T. Kearney. (2010). Consumer Product Fraud: Deterrence and Detection.