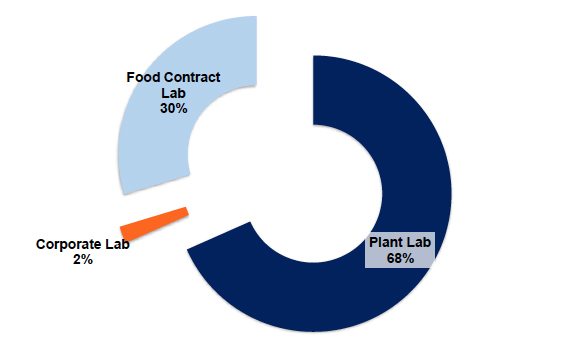

Infographic: Who Outsources Pathogen Testing?

Pathogen testing of food samples, whether in-plant or outsourced, is a critical task. Although some companies find it more cost-effective (and they have the capabilities) to conduct testing in-house, other companies don’t want to touch it due to cost and potential risk.

“Food processors are far more comfortable analyzing samples for nutritional parameters, contaminants and routine microbiology in an in-plant lab, but fewer are comfortable running pathogen tests in-plant,” stated Bob Ferguson of Strategic Consulting in the Food Safety Tech article, Changing Landscape for Selecting a Food Safety Contract Laboratory.

According to Ferguson, some of the factors that lead food processors to outsource pathogen testing include:

- Need for skilled analysts (including recruiting and maintaining accreditations

- Lab accreditation (just 20% of food company labs are accredited)

- Analytical methods require complex equipment, which can be expensive to maintain

- Risk of in-house pathogen contamination

- Company size

The below infographic reveals some of the findings, discussed at the 2016 Food Safety Consortium, of a survey conducted of more than 100 food processing customers of food contract laboratories.