Training plays a crucial role in the FSMA Preventive Controls rule. As online learning becomes a more integral part of employee learning, companies may want to reexamine the methods they use to boost more effective outcomes. And for companies that currently use face-to-face training, investing in a virtual approach could encourage a more proactive employee learning experience.

“Under the [Preventive Controls for] Human Food rule we have legal roles that didn’t exist before—we must create smarter career pathways for these new positions and responsibilities, such as the Qualified Individual under the PCQI, the Preventive Controls Qualified Individual, and the auditor,” says Kathryn Birmingham, vice president, research and development at ImEpik. “The compliance required for these new positions is a great opportunity to use innovative and scalable training models. This becomes even more important for ROI (return on investment) in training, when turnover is likely or when companies want to attract new talent into the food safety industry.”

In a Q&A with Food Safety Tech, Birmingham explains how companies can navigate some of the additional training requirements under FSMA and how interactive online learning may offer both employees and companies more successful results.

Food Safety Tech: What employee training challenges do today’s food companies face?

Kathryn Birmingham: As an educator, business owner and researcher who has designed certification and degree programs for workforce training in several industries, I see [that] the food manufacturing industry must move from lifetime experience training to training standards. For the first time, the evidence of QI training and PCQI credential are owned by the person as they move from company to company.

Food companies need a cost-effective training system that can assess knowledge, skills and competency standards. Industry research tells us that company leaders want training that is relevant, in which employees can apply skills right away. They want to be able to test the knowledge of persons in these new roles who are accountable for regulatory compliance. Thus they expect valid assessments in their certification training.

The demand is for smarter pathways to reach these new legal roles in the legislation for the QI and PCQI. Assisting in this area, we need to remember that food manufacturing companies view their number one job as making food, not completing paperwork or digital documentation, so when it comes to FSMA we have to come up with relevant training that can be applied right away.

FST: In what areas do you think companies are unprepared for FSMA implementation and compliance?

Birmingham: Companies seem to be least confident in terms of training in a few areas: For the legal role of the PCQI, they seem to be least confident about the record keeping requirements and foreign supplier verification areas.

For the role of the QI, standardized training doesn’t exist, but we know from the PCQI training that if the QI is required to implement the food safety plan under the PCQI, then QIs must understand components of the food safety plan and the hazard analysis. So it follows that the QI must also understand some scientific and regulatory factors related to the preventive controls along with the new language that must be used in the food safety plan and documentation.

FST: What tools or technologies should companies leverage?

Birmingham: Research and successful practice in workforce training tells us a few things. In order to speed learning and verify the trainee’s learning, knowledge and competencies, we recommend instructional methods that are immediately relevant, engaging and motivating. Effective training for food safety regulatory compliance helps the learner with stronger critical thinking for decision-making and encourages the learner to apply the skills right away. Modular instruction allows time for practice and reflection while increasing the odds of retention of the material. Relevant work simulations can teach technical and scientific knowledge as well as communication skills.

We recommend online training that demonstrates proficiency and mastery rather than passive learning. The learner must engage and practice what they’re learning, show an understanding, practice critical thinking, and pass valid assessment exercises.

FST: Do you think a lot of passive learning is happening in the food industry?

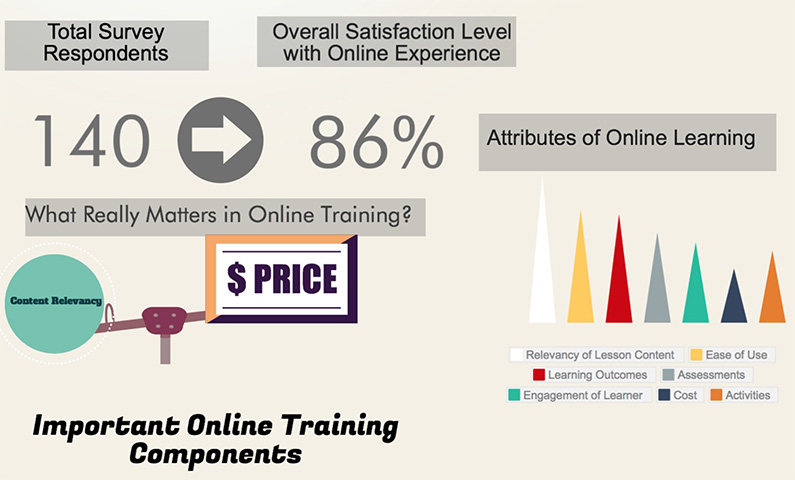

Birmingham: [Birmingham cites a food safety online training survey conducted by ImEpik earlier this year; see Table I.] Survey responses from a sample of 140 companies are telling us that they’re not satisfied with lack of engagement in training offerings. Those overseeing training would like to see more valid assessments. In terms of passive learning, they don’t want to click through voice-over narration for training or have face-to-face training that is lecture style without a lot of engagement. They want to understand the learning outcomes and what they should be getting out of the curriculum as they move through the training.

| Preference for Specific Online Learning Attributes | ||||

| I Dislike It | I Can Tolerate | I Expect It | I Like It | |

| Multi-languages | — | 10% | ||

| Valid Assessments | — | — | 91% | |

| Research-based Instructional Methodologies | — | — | 79% | |

| Learner Engagement | — | — | 77% | |

| Interactive Activities | — | — | 73% | |

| Certificate of Completion | — | — | 65% | |

| Supplementary Manual | — | — | 55% | |

| Animation | — | — | 35% | |

| Learning Analytics | — | — | 55% | |

| Table I. Results from ImEpik survey about food safety online training. While animation and learning analytics are not as expected in online learning, these attributes are an important part of simulating the work experience in order to apply new knowledge, test specific content areas for clarity and assist the learner in remediation as needed. Data courtesy of ImEpik. | ||||

In the 2015 survey, 73% said they expect interactive activity in training while 91% expect valid assessment. People are looking for feedback as they progress through training. In the end they want to have the ability to prove what they know and can do.

With the emphasis now on FSMA, for companies to develop their entire food safety team, we need to rethink training and remember that it is possible to look at other industries and see what they’ve done with these career pathways for new roles that have been legislated. We can compare online training that is accessible anywhere and agile enough to train for new concepts quickly. Science and GMPs change. This is where a tool like online learning—not only full-course certification courses but also micro-learning modules—can really help the industry. And in the long run, it could be a better return on investment than face-to-face and long-term experiential learning.