In recent years, foodborne illness has ignited alarming concerns across the globe. Food products can become contaminated with pathogenic bacteria through exposure to inadequate processing controls, animal manure, improper storage or cooking, and cross contamination. The following is a look at some of the pivotal figures that illustrate the effects of food contamination:

- • According to WHO, an estimated of 600 million people globally fall ill after consuming contaminated food, of which 420,000 succumb to death every year.

- Children under 5 years of age carry 40% of the foodborne disease burden, with 125,000 fatalities recorded annually.

- Regionally, CDC reports suggest that foodborne pathogens cause nearly 9.6 million illnesses, 57,500 hospital admissions, and 1,500 deaths yearly in the United States alone.

- Considering the financial aspects, it is essential to note that about $110 billion is lost almost every year in productivity and medical expenses from unsafe food consumption in low-and middle-income economies.

With such daunting numbers taking over the globe, there stands an innate requirement of cost-effective, easy-to-use, and accurate testing methods that ensure the consumer is delivered nothing but the safest food.

It has been estimated that global food pathogen testing market size could potentially surge to $5.5 billion by 2024.

Why is pathogen testing necessary? Pathogen testing is generally carried out to decrease and remove foodborne illnesses. It is a technique implemented in the very nascent stage of food production to ensure proper sanitation and food safety. The testing can be done using conventional technologies or the cutting-edge methods, including Polymerase Chain Reaction (PCR) or an immunoassay test.

PCR technology:

An ideal and convenient technology in use for pathogen detection in food industry

PCR is one of the most frequently used technologies. The test enables the detection of a single bacterial pathogen, including E. Coli, Salmonella and Listeria, present in food by detecting a specific target DNA sequence. Aiding to such advantages, various business conglomerates that are involved in the food pathogen testing industry are taking strategic measures to bring forth novel innovations and practices in the space. The following is a brief snapshot of some developments in the PCR based pathogen testing technology landscape:

- Sanigen, Ilumina partnership for development of NGS panel

Owing to the escalating demand for PCR testing technology for detecting the presence of food pathogens, South Korea-based Sanigen, recently announced standing as a channel partner in the region for Illumina. Both the companies, in unison, are expected to work towards the development of NGS panels that can robustly detect 16 types of foodborne pathogen from around 400 samples. - Thermo Scientific’s 2020 launch of SureTest PCR Assays

Last year Thermo Scientific expanded its portfolio of foodborne pathogen detection with the launch of the SureTest PCR Assays. The testing technology is poised to offer various food producers an access to a more holistic range of tests for every step of the analysis process.

A look at one sector:

How is the expanding dairy sector complementing the growth structure of food pathogen testing market?

The dairy production industry is rapidly expanding in various developing and developed economies, marking a significant contribution to health, environment, nutrition and livelihoods. According to a National Farmers Union report, the U.S. dairy industry accounts for 1% of the GDP, generating an economic impact of $628 billion, as of 2019. However, dairy products, although deemed healthy, can contribute to severe human diseases in umpteen ways, with dairy-borne diseases likely to top the list.

Milk and products extracted from the milk of dairy cows can house a variety of microorganisms, emerging as a source of foodborne pathogens. This has pushed the need for appropriate testing methods and technologies, which can eliminate the presence of dairy-borne bacteria, like Salmonella.

Today, various rapid pathogen testing solutions that are suitable for detecting the presence of distinct bacteria and organisms are available for dairy-based food companies. For instance, PCR-based solutions are available to test for mastitis in dairy, which is a common rudder infection caused by microorganisms in dairy cattle, affecting the quality of milk. Apparently, Thermo Fisher offers VetMAX MastiType qPCR kits for relatively faster, efficient and easier mastitis diagnostics. In fact, the kits are deemed to be reliable tools that would accurately detect all mastitis causing bacteria in frozen, fresh and preserved milk samples.

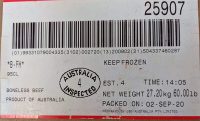

Meat Products

Consumption of raw or undercooked meat is also expected to generate a significant food pathogen testing kits demand in the coming years. Common contaminants found in these products are E. coli and Salmonella. One of the strains of E. coli, Shiga Toxin-producing E. coli (STEC), is expected to emerge as a fatal contaminant present in the meat products. Consider the following:

- WHO reports estimate that up to 10% of patients with STEC infection are vulnerable to developing haemolytic uraemic syndrome (HUS), with a case-mortality rate ranging from 3 to 5%.

- Moreover, it has the ability to cause neurological complication in 25% of HUS patients and chronic renal sequelae, in around 50% of survivors.

Under such circumstances, the demand for pathogen testing in meat products, for detecting E. coli and other contaminants is gradually expanding worldwide. In January this year, PerkinElmer introduced its new tool for detection of E. coli O157 in food products. The kit has been developed for generating rapid results while simultaneously putting them forth to support food safety efforts related to beef and its self-life.

The global food and beverage sector is subject to stringent safety requirements and a considerable part of the responsibility lies with food producers. As such, access to rapid testing technologies will enable the producers to fulfill their safety obligations without compromising on productivity and bottom lines. The consistent development of PCR-based tools will certainly outline the gradual progress of food pathogen testing industry, keeping in mind the high penetration of dairy and processed meat products worldwide.