Food retailers and the entire food and beverage (F&B) industry are now operating very differently than they did some six months ago. The pandemic has brought immense shifts in supply chains, imposed new hazard controls, and—perhaps most importantly—turned consumer preferences upside down.

To accommodate these changes, food manufacturers, retailers, restaurants and others stepped up to innovate and secure the continuity of their services. But now, as many industries begin to drop the notion of ever going back to what once was, it’s time we started thinking about how many of the newly introduced processes will stick around for the long-term.

What will be the main trends defining the food industry as a whole post-COVID?

Adopted Habits Aren’t Going Anywhere

The pandemic brought radical changes to our everyday lives, and it’s clear that many of the newly adopted behaviors won’t disappear overnight. Consumers will continue to rely on grocery retailers to keep them both fed and healthy while expecting minimum disruptions and a high respect for safety regulations—both in terms of handling and the state of delivered products.

Take-home grocery sales grew by 17% between April and July, breaking the record for the fastest period of growth since 1994. Online grocery shopping also gained popularity while managing to engage entirely new demographics. Some 10% of baby boomers now say they would buy more groceries online once the pandemic is over—compared to 34% of Gen Xs and 40% of millennials.

Due to consumer hyper-awareness of safety and sanitation, the whole food industry will continue to be defined by safety practices. Sanitizing common surfaces like keyboards, door handles, tables and chairs regularly will remain the norm. Beyond “manual” rules such as the mandatory use of facemasks, requirements such as regular health checks could boost the adoption of technology across the industry—transforming not only customer-facing interactions but also the processes behind the curtain.

Technology as an Enabler

Every crisis sparks innovation, and the food industry has certainly proved this thesis. Technology has become the ultimate aide, enabling interactions that would otherwise be impossible. These include contactless ordering, payments and pickup—processes that are likely to stick around even beyond COVID-19.

At the same time, the pandemic accelerated the usage of innovations that previously struggled to become mainstream. This includes virtual tipping jars or mobile order-and-pay, such as the options introduced by fast-food giants including McDonald’s, Subway, KFC, and Burger King.

There’s an obvious appetite for F&B companies to further incorporate technology. For example, the Coca-Cola Company is rolling out a touchless fountain experience that can be used with a smartphone for contactless pouring. Heineken, on the other hand, turned to virtual tech to launch a new product—a cardboard topper for multipack beer that will eliminate plastic from millions of cans. With travel restrictions hindering the mobility of engineers, the company leveraged virtual technology to install the new machinery needed at its Manchester-based factory.

But it’s not just solitary innovations; the market has already seen new AI-based technologies that help food businesses better manage risk in their workforce. Food manufacturing, distribution and provision require many different touchpoints; by predicting, monitoring and testing the health and safety of the workers involved in these processes, companies can ensure they keep their operations running, even if another wave of COVID-19 hits. Solutions like these will be crucial when looking to add another layer of safety that goes beyond mandatory governmental regulations.

Food Safety Revamped

Even though COVID-19 is transmitted through airborne respiratory droplets, and the risk of contracting the virus through food is low, people around the world are concerned about the possibility. After all, 40% of people are more careful about washing unpackaged fruit and vegetables than before the pandemic.

The pandemic has already made societies rethink various established concepts, such as wet markets or the consumption of wild animals. The pandemic could, therefore, lead to changed behaviors, and newly imposed rules such as formalizing small and micro food enterprises, provisions for direct sales by farmers, leveraging technology to ensure safety, and investments in a more robust food infrastructure altogether.

Such changes could also irreversibly affect street food—a sector that is bound to feel the hit of COVID-19. Particularly in countries with diverse street food culture, one of the emerging trends will be the rise of gourmet street food brands that can provide both great taste and high hygiene standards.

Food Sustainability to the Forefront

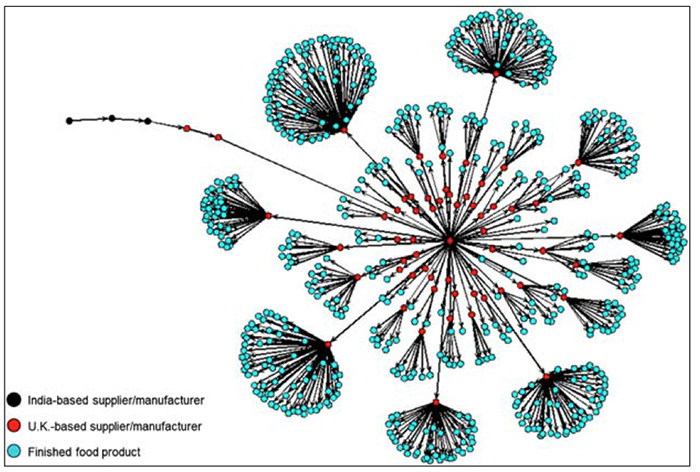

2020 will be a year of reckoning for the world’s food systems. The pandemic exposed the flaws of the global food supply chain that continues to be highly centralized and operating on a just-in-time basis. This is why we have seen panic food runs, urgent supply shortages and high amounts of food waste as many businesses were shut down overnight. In developing countries, several agencies expect that a “hunger pandemic” and a doubling of people starving could happen unless serious action is taken.

As we rethink the underlying principles of the food industry such as safety and supply, other concepts such as transparency and visibility into product sourcing and manufacturing also come into the spotlight. Consumers across the globe are more likely to prioritize offerings that are healthy and locally sourced than they were before COVID-19.

Food produced with the overuse of chemicals in monoculture cropping systems and large-scale animal farming significantly impact the availability of natural resources and cause substantial greenhouse gas emissions. Added to that, practices like industrial animal farming that operate with large numbers of livestock in confined spaces are a breeding ground for viruses, and have been linked to prior outbreaks such as the outbreak of swine flu in 2009. They also enable the spread of antibiotic-resistant organisms due to the common overuse of antibiotics administered to prevent infections caused by cramped living conditions.

Consumers are increasingly aware of this: Nearly 25% of Americans are now eating more plant-based food. As we move forward, diverse food companies are likely to tap into this trend, resulting in great opportunities for plant-based, nutritious, local, and even healthy DIY meals and products. For example, an Australian food producer has recently announced the launch of a new proprietary product range that will offer the first vegan ready-to-drink protein shakes on the Australian market.

A New Way of Dining

The restaurant market has been one of the direct victims of the pandemic but has shown impressive elasticity in adapting to the new realities. Many businesses have introduced service extensions such as deliveries and take-outs, as well as pop-up grocery stores. Enjoying great popularity, some of these options will stick around far beyond the pandemic.

However, there’s a counterforce hindering significant expansion: The simple fact that many consumers discovered a new joy in cooking. A recent study notes that 54% of Americans are now cooking more than they were before the pandemic, with 35% saying that they “enjoy cooking more now than ever.” But at the same time, 33% of consumers say they’re getting more takeout than before the pandemic. This implies that the post-pandemic normal will likely see a shift toward eating at home more often, whether that means cooking or takeout and delivery.

Therefore, restaurants are likely to continue diversifying their services, experiment with food bundles and DIY meal kits, or even luxurious in-home chef visit experiences as an alternative to high-end restaurant dining.

The past crises have shown that economic uncertainty is directly linked to changes in demand for private-label and value brands. After the 2008 financial crisis, 60% of U.S. consumers were more interested in reasonably priced products with core features than in higher-priced, cutting-edge products. So while luxury dining is not completely disappearing, it could take on other aspects.

In Denmark, for example, a two-Michelin star restaurant is moving to serve burgers. In China, a country that many look to as the model for the post-COVID world, there has also been a clear push toward more affordable dining as well. Hot pot and barbecue venues have been thriving, particularly among customers in their 20s and 30s. Many fine dining restaurants, on the other hand, have started offering affordable lunch menus or have cut prices to correspond to the current value-conscious behaviors.

It’s clear that the future of food retail and the F&B industry will be significantly marked by the pandemic. Its prolonged nature will also cause the newly adopted habits to become further solidified—and many processes will adapt to match them. For example, while contactless deliveries were accelerated in the past months, businesses are working hard to make them as efficient as convenient as possible, making it unlikely that such investments would be erased overnight, once COVID-19 is no longer a threat.