Training is one of the foundational principles of every food safety program. It is a theme that’s repeated throughout governmental regulations, industry guidelines, and audit requirements, but adult learning can be challenging. It is also expensive, when you factor in the resources needed, salaries of everyone involved, and loss of operational productivity. After all these resources are allocated, it’s frustrating to witness mistakes made by those that have gone through the proper training…so you “retrain” as a corrective action, only to see the same thing happen. When this cycle repeats itself, I can’t help but be reminded of Albert Einstein’s definition of insanity, “Doing the same thing over and over and expecting different results.”

A true preventive measure may be to reevaluate your training methods and train smarter, not harder. Take time to really understand your audience, discover their motivations, and devise ways to truly reach them. The five cornerstones of teaching: legitimacy, authenticity, engagement, empowerment, and simplicity can be used to elevate any training program to make it more effective.

Legitimacy

Your audience will be much more open to receiving the subject matter if they believe in the legitimacy of the source, namely, the trainer. Objectively ask yourself, “Why should I be teaching this class, and why should these people believe what I say?” Take the time to establish yourself as a subject matter expert. Instructors often start with a quick bio slide to explain their qualifications and experience. You can also start by telling your audience a bit about yourself, including your educational background and experience. Also take the time to explain the “why” of what you are teaching. For example, we don’t allow jewelry in the processing room, because it could fall into product or could get caught in a conveyor and cause a serious injury.

Authenticity

Why should these people care about what you say? Steven Covey, author of “The 7 Habits of Highly Effective People” also wrote the book, “The Speed of Trust.” In this book, he explains that trust is the foundational principle that holds all relationships together and the most essential ingredient in effective communication.[1] Establishing trust and authenticity is the quickest means of taking a training from you talking to people to having them hear what you are saying. Some people are automatically suspicious, so being honest and straightforward goes a long way to gaining that trust.

Engagement

I’ve been training adults for my entire 21-year career—see how I started establishing legitimacy with you—and I’ve learned that training is about 90% entertainment and 10% relaying facts and hoping they stick. Remember your favorite teacher. Were they boring and monotone, or lively and engaging? Engagement can be achieved by actively getting your audience to participate. This can be done through verbal quizzes, break-out exercises, live polls, and asking them to share their experiences.

At the end of the day, engagement is coupled with the question, “Why is this important to me?” How do you make the subject matter important to the audience? How can you get them invested in the subject matter and motivated to implement what they’ve learned? When dealing with food safety subject matter, one way is to share foodborne illness statistics and stories of those who have been affected. Stop Foodborne Illness has captured many of these stories on its website. When you identify something that everyone has in common, namely, that we and our loved ones all eat the food that we are producing, it increases audience engagement.

Empowerment

Once you have an engaged audience, the question becomes, “What can I do about it?” By telling the audience what they personally can do to influence (prevent, reduce or, eliminate) the problem, they are more likely to have a vested interest in the outcome.

I was involved in opening a new facility a few years ago. The General Manager personally took every new hire for a tour of the facility to explain the machinery and demonstrate some of the workplace safety features. While on that tour, he told them that each person in this building was allowed to hit the E-Stop button at any time and shut down the line if they saw something wrong or suspected that something wasn’t right, with no repercussions. He emphasized the importance of the subject of food safety by empowering each person with the authority to shut down the line. By giving them this power, he ensured that every person was captivated by the safety training and took the message to heart.

Simplicity

One of my personal mantras is, “Simplicity is the key to sustainability.” The simpler you make something; the more likely people will be to do it correctly and keep it up over time. The more complicated you make something, the less effective it becomes, especially over time. I use this quote when talking about creating procedures, but it’s applicable in the training setting too. The more complex the training, the harder it is to understand. The longer the training, the harder it is to captivate your audience, as people often “check out” and stop paying attention, especially if they’ve worked a long shift and just want to go home. I’ve found that shorter, interactive trainings can be more impactful than longer sessions.

One of my most successful training sessions was as a temporary QA Manager, trying to ensure that the annual training requirements were performed, prior to an audit. I asked the attendees they’d done in the past and got an eye roll along with grumblings about PowerPoint presentations. I decided to try something different and created about 10 “slides” on chart paper and held the training while we stood in a quiet corner of the warehouse. My first group was the third-shift sanitation crew. We spent 20 minutes going over the big concepts, joking about my horrible illustrations, and sharing stories about the subject matter. Afterwards, I asked them how they liked it and got some genuine nods and smiles. I decided to repeat the session with the rest of the processing employees and all the office staff (warehouse setting and all). I was shocked how many people came up to me afterwards and told me how much they enjoyed the session and appreciated the change.

Case Study, “Don’t Throw-Up Worms!”

One of the most effective food safety campaigns in history was the effort to slow cases of Trichinellosis, a foodborne disease that was sweeping the country in the early 1900s. The government’s strategy included new regulations for swine feed and educating the public of the dangers of eating undercooked pork. It started in the 1920s, when Benjamin Schwartz, Senior Zoologist with the Bureau of Animal Industry published a leaflet for the USDA entitled, “Trichinosis: A Disease Caused by Eating Raw Pork.”[2] As a result, the government started surveillance activities to understand the extent of the problem. In the 1930s and 1940s, it was estimated that one in every six Americans was infected with Trichinella spiralis,[3] so the U.S. government implemented a widespread campaign to educate the public.

This campaign, which was so effective that Trichinella is almost unheard of in domestic pork today, worked because they leveraged the five cornerstones to create an extremely effective training.

- Legitimacy – The U.S. government was a trusted source of knowledge.

- Authenticity – This message was backed by doctors and scientists from the CDC and other agencies. Also, people knew that pork was the making them sick, so this information was verified by personal experience.

- Engagement – Because scientists had discovered that Trichinella is a microscopic parasite, they coined the phrase, “Don’t Throw-Up Worms!” since vomiting was a common symptom, and that caught everyone’s attention.

- Empowerment – The general public had a tremendous amount of control because the solution focused on fully cooking pork at home or ordering pork chops “well done” at restaurants.

- Simplicity – The solution was extremely easy, just cook your pork a little longer. If it’s easy, people will do it, and they did.

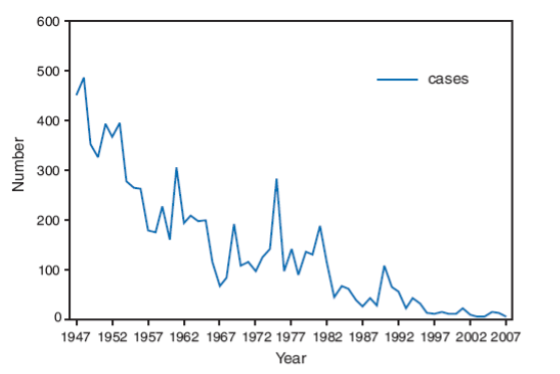

Let’s look at the results. Between 2002 and 2007, the CDC only recorded 52 cases of Trichinellosis and only seven of those were traced to commercial pork.[4] The figure below shows the number of reported cases of Trichinellosis in the U.S. from 1947-2007, and the steady decline is evident.

Trying a New Approach

Occasionally, you’ve got to mix things up to keep your audience interested. There are so many different training tools that are available on the internet, from YouTube videos (my favorite is a rap about handwashing) to novel ideas. You can also change up the setting; try standing in an unusual place in the facility or host a training outside or on the facility floor.

Make sure that you are thinking about your target audience when creating your training. Use language that’s appropriate and techniques that resonate. This might take a little trial and error, so don’t be afraid to try new things and discard the ones that don’t work well.

As Gen Z and Millennials overtake older generations as the majority of the workforce, there has been a lot of research into effective training for younger generations. One technique that is garnering a lot of interest is gamification. I’ve seen video games that replicate a chef at a busy restaurant, in which good manufacturing practices must be used to fulfill multiple orders. This might be more effective than sitting an 18-year-old down for a four-hour ServSafe training. It doesn’t have to be as complex as a specially designed video game, I’ve seen things as simple as food safety word searches and crossword puzzles that are left in the breakroom. Trivia is also a popular and engaging tool to use during training sessions, especially when there are fun prizes on the line.

Reconsider your approach to training by implementing the five cornerstones of teaching and trying novel approaches. Even small changes can make a big difference. Reach out to your colleagues to learn what has worked for them, and try new tools to help make these sessions more enjoyable for all the participants which will directly increase the effectiveness of your training program.

References:

[1] Covey, Stephen M. R. 2008. The Speed of Trust. London, England: Simon & Schuster.

[2] Schwartz, B. 1929. Trichinosis: A Disease Caused by Eating Raw Pork. USDA Leaflet No. 34; 1-12. https://archive.org/details/trichinosisdisea34schw/page/n1/mode/2up

[3] Most H. Trichinellosis in the United States: Changing Epidemiology During Past 25 Years. JAMA. 1965;193(11):871–873. https://jamanetwork.com/journals/jama/fullarticle/656503

[4] Kennedy, E. E. et al. 2009. Trichinellosis Surveillance – United States, 2002-2007. CDC MMWR. 58 (09); 1-7. https://www.cdc.gov/mmwr/preview/mmwrhtml/ss5809a1.htm