Many people associate terrorism with spectacular attacks such as those that occurred on September 11. However, lone wolf attacks are far more likely to happen in what has unfortunately become the new normal. “The last thing on your mind is a terrorist being interested in food. It does exist, and bad guys do have an interest in this area,” said Special Agent Scott Mahloch, weapons of mass destruction coordinator for the Chicago division of the FBI during the Food Safety Consortium last week. What does this mean for the food industry?

SA Scott Mahloch will present FBI’s Role in Food Defense on November 29 at the 2017 Food Safety Consortium | Learn moreAccording to the Department of Homeland Security, with 2.2 million farms and 900,000 restaurants in the United States, the food and agricultural sector accounts for 1/5 of the national economic activity. There are several industry targets for terrorism: Food processing facilities; food storage and distribution; restaurants, grocery stores and markets; commercial facilities; and cruise lines.

While Mahloch emphasized that there is no imminent threat to the food sector, one of the biggest areas of concern for this particular industry is the insider threat. “The insider threat is that person [who] knows the facilities, processes, distribution network and can cause the greatest impact,” said Mahloch. This can be in the form of a disgruntled employee who has or can gain access to equipment or other areas of a facility that would otherwise be secure and then introduce contaminants into food products. Mahloch stressed the important role that a food company plays in monitoring employees and reporting any deviation from normal behavior. This is not an easy task—in fact, it is the most difficult threat to detect, and the most difficult threat to protect against, Mahloch pointed out.

Insider Threat: The threat posed by an individual who exploits his/her position, credentials or employment to achieve trusted access to the means, processes, equipment, material, location, facility and/or target necessary to carry out a terrorist action.

The likelihood of an employee becoming an insider threat increases with a variety of personal factors, including financial need, feelings of anger or revenge, being a sympathizer with terrorist ideology, having problems at work, compulsive and destructive behavior, ego and family issues. Food organizations also open themselves up to vulnerabilities via the following:

- Allowing easy access to restricted or sensitive areas within a facility (i.e., not limiting personnel access to certain areas or clearly labeling access controls)

- Failure to have physical security controls over personal items that are either brought into or taken from the workplace

- Vague security policies/Lax security perception

- High employee turnover

- Lack of proper employee vetting

- Failure to train employees in proper security protocols

- Failure to have consequences for violating security policy

Surveillance

When assessing the insider threat, what should food companies look for in an effort to protect their facility and products? “You’re the first line of defense,” said Mahloch. “We get a lot of phone calls where people run things by us. If something doesn’t seem right, say something.” He provided several key behaviors that may be characterized as suspicious in some instances:

- Someone taking a photograph or video, or notes/sketches, of food processing operations or sensitive areas

- Someone attempting to gain information about company operations, especially related to security and personnel, in person, or by phone or email

- Someone conducting surveillance of self services areas such as salad bars, condiment stands or open bulk containers

- Shipping area: Unscheduled deliveries, driver who is unfamiliar with facility delivery protocols, items left on dock at unusual hours, illegally parked or unattended vehicles, or shipping documents that don’t match

Be Proactive

Companies can take several preventive steps to protect their facilities, products and personnel. Proactive measures include:

- Monitoring products for evidence of tampering, resealing or damage

- Securing open containers of food or ingredients in storage areas

- Controlling access to specific areas of facility by delivery personnel, employees, vendors and contractors, and general visitors

- Securing loading dock area, and standardize delivery and pickup protocol

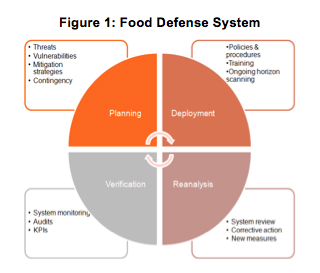

- Developing a written food defense plan

- Training employees, contractors and vendors to recognize suspicious activity and report it accordingly

Take Action

It’s important to stay alert and be aware—employee observations are critical, said Mahloch. Once suspicious activity is observed, the facility security officer or manager should be notified, and from there a decision can be made on whether external parties need to be involved. In general, state and local partners investigate an incident before the FBI gets involved.

“When it comes to intentional contamination [or a] terrorist incident—that’s an area that we investigate and ultimately prosecute,” said Mahloch. He emphasized the FBI is not a regulatory agency, so it would not show up at a facility due to a company’s lack of compliance to FSMA, for example. The agency is interested in food defense and intentional contamination that has the purpose of causing harm.

For more information about the FBI’s role in food defense, the agency has a document on its website that summarizes food defense for the industry, including some of the above-mentioned factors to look for when trying to identifying suspicious behavior. If a company wants to report suspicious activity that is not an emergency, it can call 1-855-TELL-FBI (1-855-835-5324).