Can you explain, in simple terms, what hyperspectral imaging is?

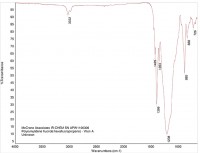

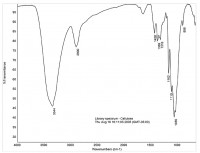

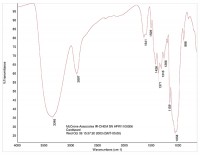

Olga Pawluczyk: Hyperspectral imaging is a form of spectroscopy, which is the science of how wavelengths of light (or really, electromagnetic spectrum) interact with substances. As different wavelengths are absorbed by atomic and molecular bonds, we can measure that interaction and determine the chemistry of the substance under investigation. Essentially, your eyes and brain form a simple 3 color spectrometer: since you see grass as green, you can guess that it contains chlorophyll. Now, hyperspectral images include full 2D spatial information (like a regular camera image) but split the light into hundreds of continuous colors (or wavelengths). Compare this to the three colors (red, green, blue) used by cameras like the one in your cell-phone. Hyperspectral imaging allows much greater precision than other types of spectroscopy.

Why is hyperspectral imaging so effective for finding foreign (FM) materials in food products?

Pawluczyk: Using hyperspectral imaging, a system can see full images of objects and chemical signatures of different materials within those images. That’s what makes this technology so much better than other forms of vision or spectroscopy for distinguishing materials such as clear plastics, rubber and bone that are often hard to see on the line. Not only do we see the chemistry, but can also distinguish very small objects that differ in their chemistry from their surroundings. We can do this on line, at line speeds. PPO’s hyperspectral imaging system has been developed specifically for food processing, with rigorous testing and unique spectrometer design that allows us to see a lot of chemical information, while still enabling producers to run their lines at full speeds.Combining this with our powerful artificial intelligence (AI) engine makes our system uniquely effective at line speed, meaning contaminants can be identified and removed immediately.

What are the advantages of hyperspectral imaging over other types of detection systems?

Pawluczyk: In addition to being highly effective at finding FM, an important advantage of hyperspectral imaging is that it also enables us to see the composition of food products. Since food is chemistry, we can use hyperspectral imaging to assess different chemical properties of food products. For example, our testing has shown that spinach grown in different parts of the same field will have slightly different chemistry. Hyperspectral imaging can see those differences, so we can identify many different quality issues such as woody breast in chicken, fat/lean ratios, freshness and moisture content.

How can food processors use this information on composition and quality?

Pawluczyk: PPO’s Smart Imaging System uses an AI engine to collect and process the data from our imaging system; It ‘learns’ over time and gets even better at detection of FM or quality issues. It also means that PPO’s system can spot trends in your production. For example, using PPO’s technology, one of our clients was able to identify and correct an issue with their de-boning process, which helped them reduce customer charge-backs by 40%.

How confident can processors be that the system will catch the FM and quality issues they care about?

Pawluczyk: Part of PPO’s installation process with a new client is a very thorough testing process. Our team of experts works closely with our client to configure each system to the precise conditions of the plant and the products that are being processed. Using AI, our Smart Imaging System gathers and stores all this information, so it learns over time and is continuously improving.

What makes PPO’s Smart Imaging System different from other visual inspection systems on the market?

Pawluczyk: PPO’s is the only hyperspectral imaging system that is operating on the line in multiple plants across North America. It is being used in a variety of poultry and pork processing facilities and has proven to be highly effective in finding a wide range of foreign materials.

Ultimately, we think happy clients are the greatest proof that our system is working. We’re seeing repeat orders starting to come in from existing clients as they reap the cost benefits of improved detection in their plants.

Learn how food processors can leverage hyperspectral imaging on P&P Optica.

Content sponsored by P&P Optica.

About Olga Pawluczyk

About Olga Pawluczyk

President, CEO and Co-Founder

P&P Optica

Olga Pawluczyk is the co-founder and CEO of P&P Optica (PPO), based in Waterloo, Ontario, part of Canada’s largest and fastest growing tech community. Pawluczyk is an expert in medical imaging, with a technical background in systems engineering and deep knowledge of the science of spectroscopy. Under the leadership of Pawluczyk and her co-founder, her father Romek Pawluczyk, PPO launched in 2004 as a research company focused on developing high-end spectrometers. The company has evolved over the past eight years to focus on building solutions to the issues of safety and quality in the food processing industry. Pawluczyk is driven by the opportunity to combine emerging technologies to significantly improve the nutritional quality, safety, and sustainability of our food.

As a leader, Pawluczyk focuses on providing an engaging working environment to like-minded people who are excited to explore new challenges as part of the PPO team. Outside of PPO, She is active in the local tech community in Waterloo Region; is an avid reader who loves to discuss pretty much any topic over coffee (or wine); and enjoys spending time walking and biking.