All seven core rules of FSMA require general training of individuals or employees and qualified individuals requiring education, training or experience to perform specific tasks. By including training in these regulations, the FDA has made specific training mandatory.

Training Required by FSMA Final Rules

In the current Good Manufacturing Practices (cGMP) and preventive control rules, as per 21 CFR 117.4 and 507.4, all individuals engaged in the manufacturing, processing, packing and holding of food must have the education, training or experience to perform assigned duties and must be trained in the principles of food hygiene and food safety. However, the preventive controls qualified individual (PCQI) and qualified auditor, to rules 21 CFR 117.180 and 507.53, can be an individual who has successfully completed a class equivalent in curriculum to that recognized by the FDA, or have the necessary job experience. In both cases, the training must be documented, including the date of training, type of training and those personnel trained.

This means that all employees are to be trained in food hygiene and food safety to at least the standard presented in the regulations and more specifically as per the cGMP requirements. Additionally, individuals who are responsible for a specific critical control point will still need to be trained in HACCP. However, this will probably not be sufficient for an employee responsible for preventive control, as he or she may require training in Hazard Analysis Risk-Based Preventive Control (HARPC), or training specific to the area in which the employee is involved (e.g., allergens, sanitation, supply chain or recall programs, or preventive controls).

For the preventive control qualified individual and qualified auditor, the training needed may be that of the approved FDA curriculum, as developed by the Food Safety Preventive Control Alliance (FSPCA). Although this training course is not a regulatory requirement, FDA inspectors and other regulatory personnel who are auditing facilities will have completed this training, meaning qualified auditors will be expected to have this training, and eventually preventive controls qualified individuals (PCQIs) will be expected to do so too. The qualified auditor and a PCQI will still require the education, experience and other training to perform the specific job duties as listed in the regulations. Unfortunately, it is likely that neither the industry nor the government will have enough lead instructors ready to train everyone who would want or need to be trained before the compliance dates become effective. Additionally, this training course is not yet available for animal food, and the industry has been informed by FSPCA that a Foreign Supplier Verification Program (FSVP) training module will be added to the training course. The FSVP is discussed in the Supply-Chain Preventive Control module, and the fact that there are some similarities between these regulations helps individuals involved in the FSVP program, or in auditing it.

In the produce safety rule, training requirements are listed in subpart C 21 CFR 112.21, 112.22, 112.23 and 112.30. Personnel who require training are those handling covered produce and their supervisors. As with the cGMP and preventive control rules, the principles of food hygiene and food safety must be taught to these personnel. More specifically they must learn how to identify an ill or infected person, and be taught about microorganisms of public health significance, such as Salmonella, Listeria and E. coli O157 on food contact surfaces. Additionally, personnel who harvest covered produce must be trained in recognizing produce that is contaminated with known or reasonably foreseeable hazards to ensure it isn’t harvested. These personnel must be trained in the use of harvest containers and equipment to ensure that they are functioning properly, clean and maintained, and to identify when they are not. At the same time, employees must be trained in correcting any issues or in reporting them to a supervisor in order to have them corrected. All this training must be documented in the same way as the cGMP and preventive control programs.

Unlike the cGMP and preventive control rules, the produce safety rule’s requirement to have a qualified individual, supervisor or responsible party on each farm that has completed a recognized FDA course, or equivalent, is not optional. This course will be available through the Produce Safety Alliance and is anticipated to start in September 2016. The grower food safety course required for supervisors will include an introduction to produce safety, worker health and hygiene training, soil amendments, wildlife, domestic animals and land use, agricultural water, post-harvest handling and sanitation, as well as how to develop a food safety plan.

The training for produce, conducted by the Produce Safety Alliance and/or trained trainers, does not cover training for sprouts; training for sprouts is being developed by the Sprout Safety Alliance and will include topics specifically for sprouts, such as antimicrobial treatment of sprouting seeds.

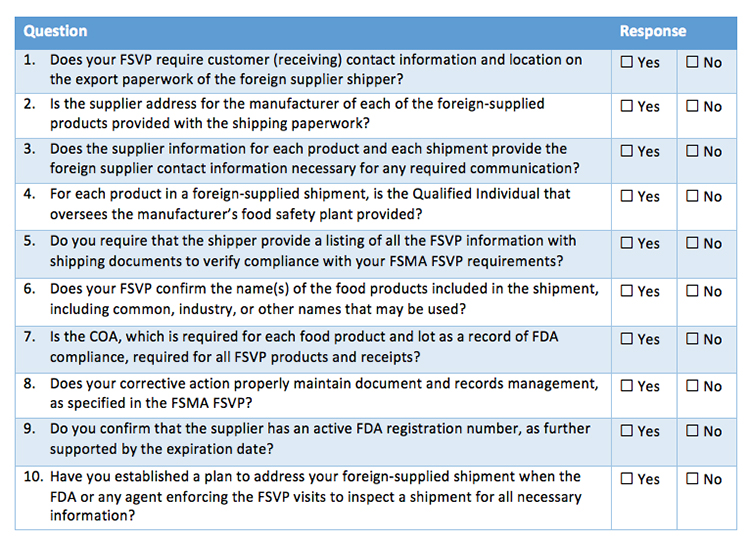

In the FSVP, the qualified individuals must have the education, training or experience necessary to perform activities as per 21 CFR 1.503. These qualified individuals will develop the FSVP and those activities such as hazard analysis, supplier approval, determining verification activities and frequency, corrective actions and other activities for the FSVP. These personnel must be able to read and understand the records to be reviewed for this program. This means they must know English and may also need to know the local language at point of product manufacture or farming.

At this time there is no structured training program for these individuals, but the FSPCA training program, alongside education and experience can provide the training necessary for these people to perform the job activities. A PCQI would be qualified for the role of a FSVP qualified individual, but the FSVP probably would not be qualified for the PCQI role. This is because the activities in the FSVP are not as complicated as those required by the cGMP and preventive controls rules, and therefore the FSVP qualifications would not need to be as stringent.

Training Under Proposed Rules

In the proposal for Sanitary Transportation of Human and Animal Foods, 21 CFR 1.910, the FDA requires carriers of these products to train personnel who are engaged in transportation operations. This should include awareness of potential food safety problems that may occur to food during transport, basic sanitary practices that would address those problems and the responsibilities of the carriers in the regulation. As with all training in these regulations, the type of training, who was trained and when they were trained must be documented.

Since this is a proposal, the training for teaching the carrier’s responsibility is not yet finalized but will require nothing more than explaining that section of the regulation. The training of potential food safety issues and the problems that might occur during transport are handled during standard cGMP and food safety training.

For the proposed Intentional Adulteration rule, per 21 CFR 121.160, the personnel and supervisors assigned to the actionable process steps must receive training in food defense awareness and their responsibilities in implementing the migration strategies. Also, as per 21 CFR 121.130, the vulnerability assessment is to be performed by a qualified individual, and this individual is to be qualified through experience and/or appropriate training.

For basic food defense, the FDA offers various courses and information, such as Food Defense 101, on their food defense webpage. An online course is offered in English and Spanish and covers the awareness training and the regulations for employees. Upon course completion, a certificate is provided. The agency also has a downloadable food defense plan builder that can be used to develop a food defense program. The agency also provides vulnerability assessment software, but additional training in PAS 96 or ISO/TS 22000 food defense would aid qualified personnel in making sure that this vulnerability assessment is correct and that the strategies to reduce risks are appropriate and not excessive.

There is an abundance of training courses and materials available from the FDA, USDA FSIS, associations and industry. FSMA employee training requires having personnel with the proscribed education and experience to perform specific tasks, and that they be trained as soon as possible in order for them to develop the programs. Additionally, all personnel should be trained at least annually in food hygiene, food safety and food defense.