Research shows the global high pressure processing (HPP) food market to be worth $14 billion in 2018. By 2023, the market will reach an estimated $27.4 billion and will grow to $51.1 billion by 2027, according to Visiongain, a UK-based business intelligence company. This growth is a result of many factors, including consumer trends, food safety and food industry demand.

One of the biggest consumer food trends is the clean label movement. Consumers are more attentive to what they eat and drink than ever before, requesting more information about the products they buy and consume. For instance, 73% of U.S. consumers agree it is important that ingredients on a food label are familiar and would be used at home, according to Innova Market Insights, a market research firm for the food and beverage industry.

Consumers want fresh, convenient and less processed foods and beverages. Shoppers, especially millennials, are willing to spend more money to receive better-for-you products, and they are also more willing to research production methods before making purchases.

On the industry side, due to an increasing concern over food safety and the rise in foodborne illness, food producers and retailers are seeking reliable food safety and preservation methods that will help ensure the best product quality. Not only do they want to keep their customers safe, they also want to ensure their brand is protected.

Food waste and sustainability is also important to consumers and industry. In the 2017 Nielsen Global Sustainability Survey, 68% of Americans said that it is important that companies implement programs to improve the environment; 67% will be prioritizing healthy or socially-conscious food purchases in 2018; and 48% will change their consumption habits to reduce their environmental impact.

Companies want to be responsible and make sure good food does not go to waste. Longer shelf life decreases a product’s chance of ending up in a landfill. Additionally, the longer a product lasts, the further it can be safely distributed and sold.

What is HPP?

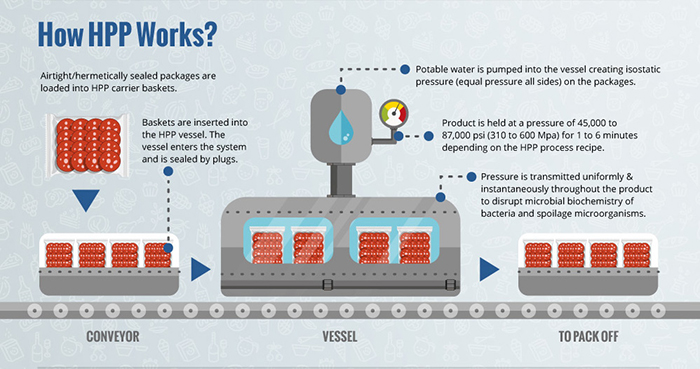

High pressure processing (HPP) ironically isn’t really processing at all. HPP is a unique food preservation method that utilizes cold water and extreme pressure (up to 87,000 psi) to inactivate foodborne pathogens and spoilage organisms.

The effectiveness of the HPP process depends on the amount of pressure applied, vessel holding time, temperature, product type and targeted pathogens and spoilage organisms.

Unlike chemical and thermal treatments that can compromise flavor, vitamins and nutrients, HPP is a non-thermal, non-chemical process. Without the use of heat, the product’s original qualities remain intact. Also, because water pressure is applied uniformly in all directions, HPP foods retain their original shape.

Current and New Applications for HPP

One of the most popular uses for HPP is for proteins, including roast beef, chicken, pork and ground meats like turkey, chicken and beef. Other uses include premium juices, dips, wet salads, dairy and seafood, as well as pet food.

Some of its newer applications are in the preservation of baby food, premium juices, plant-based protein drinks, cocktail mixers, nutrient dense shots, coffee and tea selections and bone broth. HPP is widely used for ready-to-eat meats, dips, guacamole, salsa and hummus. Raw pet food, which has been affected by Salmonella and other pathogenic outbreaks in recent months, is also a growing market for HPP. Just like for their own food, pet owners are demanding fresh, non-processed foods for their pets. HPP is a proven means of creating a safe, clean-label raw pet food.

While food safety is still the number one reason for HPP, many manufacturers and retailers also cite shelf-life extension as a major benefit. Table I is a breakdown on the type of food, shelf-life extension and key benefits of HPP.

| Food Type | Applications | Shelf-Life Extension | Key Benefits |

| RTE (Ready-to-Eat) Meats | Sliced, cooked meats: chicken, turkey, ham and beef; uncured ham and sausage | Greater than 2X | Extends shelf life while addressing common vegetative bacterial concerns. Allows manufacturers and retailers to offer reduced sodium products. |

| RTC (Ready-to-Cook) Meats | Ground meats such as turkey, chicken and perhaps beef. | 1.5X to 2.5X | Increase food safety while extending product shelf life. |

| Guacamole, Wet Salads, Salsas, Dressings & Dips | Guacamole, salsa, chicken salad, seafood salad, dressings | 2X–6X | Extends product shelf-life and reduces vegetative bacteria issues. |

| Juices and Smoothies | Super premium juices, juice blends & smoothies | 20–60 days | HPP is a natural way to deal with microorganisms and extend shelf life without the use of heat ,which can negatively affect color and flavor. |

| Dairy | Yogurt & yogurt-based dressings, cream, sour cream, cream cheese and milk. | 2X–10X | In yogurt-based products and milk, HPP is believed to give a creamier product consistency. |

| Seafood | Oysters, lobster, crab, shrimp, mussels | 2X–4X | Meat extraction (yield) is better than by hand shucking or steam methods. Labor savings in this manner makes the HPP’ing of shellfish a great application. The shelf-life extension is also significant. |

| Table I. A breakdown on the type of food, shelf-life extension and key benefits of HPP. | |||

Cost

The cost of HPP varies depending on the size of production runs, fill efficiency of the product within the HPP vessel and the HPP process parameters. The good news is the cost may be offset by other price reductions that HPP enables such as eliminating food additives. While HPP can be performed in-house, many companies outsource their HPP needs so they do not have to allocate significant capital expenses or disrupt production efficiency with an HPP batch process, allowing them to focus on their core competencies.

A Bright Future for HPP

HPP’s future is bright, with new uses on the horizon. These new uses have already resulted in new market opportunities that increase revenue. As its awareness grows among manufacturers, retailers and food service companies, and with additional education about its benefits, more companies will embrace HPP as part of their food safety program and for its shelf-life benefits. With consumer demand for fresh foods and beverages showing no signs of stopping, HPP will lead the way in helping to produce fresh, safe food and beverage products for all to enjoy.

HPP: Achieve High Standards of Food Safety Without Compromising Food Quality