Membrane filtration is a key method for determining the microbial load of filterable raw materials, products, and water. It enables the user to remove impurities from their sample that could affect the growth of organisms, while offering an easy to use process for determining bioburden levels. There are many decisions to make when considering your membrane filtration set up (manifold, vacuum source, consumable choice) and we will discuss the potential pros and cons of each choice.

What are the potential consequences of choosing the wrong manifold set up?

Michel van Musschenbroek: During the filtration of water, beverages, and other liquids, residual amounts of sample can get trapped in areas that are difficult to clean. This can eventually lead to Biofilm formation, where clusters of contaminating microorganisms become protected by a slime-like extracellular matrix. Once formed, biofilms are very difficult to eliminate and can eventually cause false positive results through cross contamination of the membrane. Selecting a manifold which enables effective cleaning and autoclaving of all components (filtration heads, valves, connections, etc.) is essential in the prevention of biofilm. Another way to improve your workflow set up is to use a direct liquid transfer vacuum pump, replacing the need for a vacuum flask (water trap).

Which filtration device type is best for sampling, re-usable or single-use?

Michel van Musschenbroek: There are many different devices available for membrane filtration. Some are re-usable such as glass or stainless-steel funnels and others are single- use (plastic disposable) units. Many believe re-usable funnels save time and are “greener”. However, stainless steel and glass funnels must be sanitized in between each sample adding time to your filtration process. In addition, using an autoclave to sterilize the equipment requires resources which often negate the “greener” theory. Cross contamination is also more likely with re-usable funnels since you are relying on proper sanitation between samples and must manipulate the membrane to perform the test. More specifically with single-use funnels, you do not have to worry about pre-autoclaving the filtration devices before sampling or sanitizing filtration devices in-between samples.

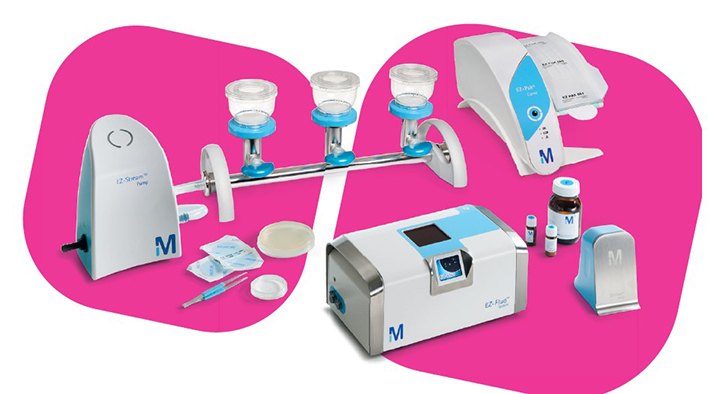

Single-use funnels and associated packaging can also be recycled in accordance with our recommended decontamination and waste sorting guidance (and pending related company policies). Most importantly, when the membrane is integrated into the device it will reduce the risk of false-positives by limiting membrane manipulation. The reasons above show why the EZ Fit family is great choice for your membrane filtration testing.

Content Sponsored by MilliporeSigma. For more information, visit SigmaAldrich.com/ez-fit