The food industry faces increasing customer demand on top of snowballing regulatory concerns, and many are calling for automation to overcome these obstacles. Automation technologies reinforce food safety practices from processing to packaging by revamping sanitation, quality control, and more.

To begin leveraging automation for food safety in your sector today, the most important areas to focus on are automated monitoring systems, growing AI/ML capabilities, and exceeding regulatory compliance.

Automated Monitoring Systems in Food Safety

Automated monitoring systems have become the titanium backbone of modern food safety, offering greater control over critical processes. With human error as a prevalent risk factor for safety incidents, companies can mitigate accidents with automated systems to mitigate this risk by standardizing processes and enforcing predefined protocols.

This paradigm shift in the way we produce food makes food safer, helps keep workers safe, and makes food quality more consistent at large. Automated monitoring systems can help reduce common errors, drive more effective sanitation, and track your most sensitive critical control points.

Error Reduction through Automated Processes

Many small, common errors can be reduced or outright eliminated with automation. In seafood processing, for example, optical sorting machines consistently identify and remove substandard products. Rather than relying on the inconsistent human eye, machines can rapidly assess each item based on precise criteria such as size, color, and texture. Automation enhances human capabilities in this way by minimizing errors due to fatigue, such as in high-volume production sites.

Consistent Sanitation Procedures

Maintaining sanitary conditions is critical for safety and regulatory compliance in food production environments. Automated cleaning systems, programmed with precise chemical concentrations and application methods, guarantee thorough and consistent sanitation. These systems meticulously track each cleaning cycle, providing auditable records for compliance purposes. In food packaging, robots can make wrapping products safer, identify foreign objects like bone/shell, and greatly reduce fatigue on workers.

Real-time Critical Control Point Tracking

Automated systems excel at monitoring critical control points (CCPs) in food production, dramatically reducing spoilage. Temperature sensors in cold storage facilities transmit continuous data streams, alerting staff to deviations before spoilage occurs. Meanwhile, automated pH meters and metal detectors in processing areas operate tirelessly with pinpoint precision to ensure consistent product quality and safety.

AI and Machine Learning Applications

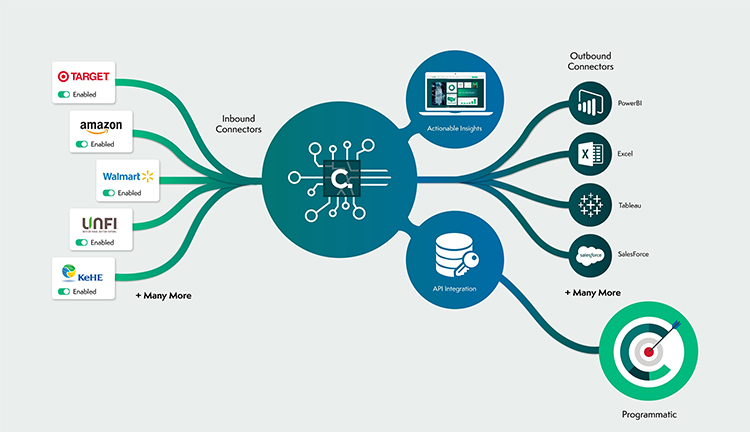

Automation can only go so far without insight. AI and ML are carving a niche alongside automation, supplementing raw power with vast datasets and analytic powers to identify anomalies. Together, they enable systems to recognize patterns, flag issues, and optimize processes in ways previously unfeasible.

These technologies integrate with automated systems to monitor complex food production networks, uncovering subtle irregularities that might be missed by human inspection or conventional algorithms.

Traceability in Food Supply Chains

Supply chains are notoriously complex and unpredictable to track because they often involve multiple stages, from raw material sourcing to processing, packaging, distribution, and retail. Each step can involve different suppliers, locations, and regulations, making it difficult to maintain a clear, real-time view of where a product has been and what conditions it has encountered.

AI and machine learning address this by continuously analyzing data from various points, creating an interconnected web of information that companies can use to trace products with greater accuracy than ever before. Whether it’s identifying the origin of a raw ingredient or tracking environmental conditions during transportation, AI-driven traceability systems provide granular insights that facility managers can use to make improvements.

Predictive Analytics

Machine learning models trained on historical data and real-time inputs can predict food safety risks before they appear. In food packaging operations, these systems analyze factors such as temperature fluctuations and microbial growth rates to track CCPs and identify issues. Across departments, predictive maintenance algorithms anticipate equipment failures that could lead to contamination. With this insight, managers can reduce accidents, cut waste, and intervene before incidents occur.

Setting Up for AI and ML

Preparation and a solid foundation in data management are essential to make the most of what AI and machine learning have to offer. Food processing facilities must prioritize data quality, storage capacity, and scalability to harness these technologies. Companies looking to adopt AI and machine learning should:

- Invest in Quality Data Collection: AI and ML require high-quality data, so IoT devices and sensors are deployed to gather accurate, real-time data across production stages.

- Choose Scalable Storage: Opt for cloud-based storage to handle increasing data volumes and facilitate easy access and integration.

- Select Flexible AI Tools: Choose AI and machine learning platforms that can adapt to changing business needs and integrate with existing systems as smoothly as possible.

- Train Staff with AI/ML: These technologies are only as good as the workers using them – provide training for employees on how to use AI tools effectively to maximize their potential.

AI can make workflows more efficient, but introducing it should always be met with deliberate planning and testing.

Regulatory Compliance and Automation

Automation tech plays a crucial role in helping food businesses navigate the complex regulatory landscape, which is subject to change. As food safety standards evolve, management should look to not just match but exceed regulatory compliance in anticipation of tightening requirements.

Robust food safety standards are essential for maintaining product integrity and consumer trust, but they only work when combined with automated documentation and reporting. Lastly, a new challenge facing food production is handling human-robot interaction in a Wild West-esque tech frontier.

Food Safety Standards

Regulatory bodies frequently update food safety standards to identify emerging risks and incorporate new scientific findings. Automation helps streamline this process for companies fighting a web of red tape by allowing for swift reconfiguration of monitoring parameters and control processes. For instance, AI-powered testing equipment can be remotely updated to detect new microbial threats without overhauling entire production lines. This flexibility helps companies stay ahead of the regulatory curve and slim costs simultaneously.

Automated Reporting and Documentation

Automated systems are stellar at simplifying food safety compliance, able to effortlessly generate and update detailed, real-time records of every aspect of food production and handling. From temperature logs to sanitation schedules, automated reporting tools compile data into a proper regulatory format and ease administrative burdens. While the primary goal is to demonstrate regulatory compliance, this data also proves itself a treasure trove for companies to improve their practices ahead of regulatory change.

Tackle Human-Robot Interaction

The concept of human-robot collaboration isn’t new, but it’s becoming increasingly more common, and the average food production worker is more likely than ever to work with a robot. This paradigm shift requires a new approach to work, which prioritizes streamlining repetitive or laborious tasks, clear communication, and continuous training as capabilities increase. It’s also worth noting that managers can alleviate worries about ‘being replaced with a machine’ by focusing on how technology supplements humans rather than wholesale replacing them in the workplace.

Final Thoughts

Automation, including robotics, AI, and machine learning, is pivotal in enhancing food safety and compliance across the industry. By using automated monitoring systems, food production sites can reduce human error and standardize processes. At the same time, AI and machine learning provide real-time data analysis and predictive insights if companies are willing to put in the work needed to prepare for automation. In that case, they can help reduce accidents, enhance efficiency, monitor food quality, and keep up with regulatory compliance at a fraction of their previous efforts.