Managing and combating cybercrime is no small feat; it can take over 200 days for companies to detect a cyber breach. The reason being cyber criminals often stay hidden even after gaining access to systems. They lie in wait for the best moment to access the information they want. Once they have it, they may use it to steal money or proprietary information or to collect a ransom. They also may sell access and information to other criminals who will take more aggressive means to exploit the organization.

Preventing cybercrime requires education and cooperation throughout an organization. Following are seven key components of cybersecurity food businesses should embrace to protect their businesses and products.

1. Education and Awareness

One of the most effective countermeasures to cybercrime is building a culture of cyber defense and awareness that empowers all employees to ask for guidance and speak up when they see a suspicious situation. Educate employees on how they can prevent nefarious activity on their computers by:

- Identifying suspicious applications with warnings and popups

- Flagging suspicious emails with hyperlinks, attachments or unknown senders

- Not clicking on links or ads from unfamiliar sources

- Verifying the trustworthiness of a site before inputting credentials

- Limiting activities on unsecured public Wi-Fi networks

This helps employees not only avoid breaches, but identify and report suspicious activity to help prevent cyber attacks.

Training should be top-down, beginning with the executive suite and department heads. This ensures that there is always someone accountable for implementing and maintaining security measures. From there, the rest of the team can be trained to assess and prevent cybersecurity threats and risks.

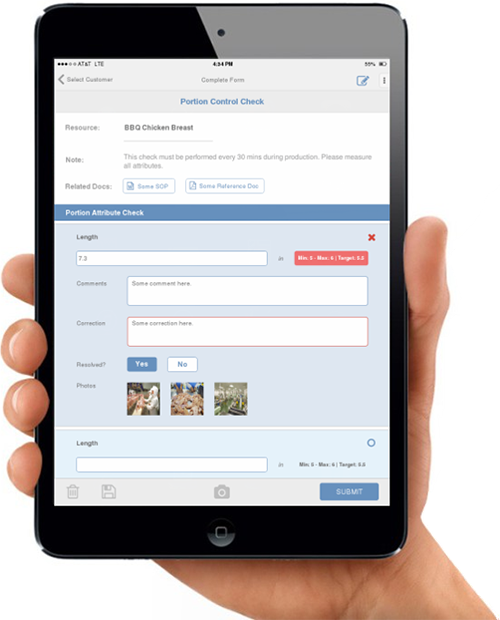

2. Implement and Enforce Mobile App Security

Mobile apps on smartphones and tablets are at risk of security breaches that can expose large amounts of user data. All mobile apps have security controls to help developers design secure applications, but it’s up to the developer to choose the right security options.

Common problems with mobile apps may include:

- Storing or unintentionally leaking data that could be read by other applications

- Using poor authentication and authorization checks that could be circumvented by bad actors

- Using data encryption methods that are vulnerable or easy to break

- Transmitting sensitive data without proper encryption online

A simple app may not seem like a big deal, but they can allow a hacker to gain access to employee computers and networks. The following measures help improve mobile app security:

Guard sensitive information. Confidential data stored in an app without security measures in place are a target for hackers using reverse-engineering codes. The volume of data on the device should be reduced to minimize the risk.

Consider certificate pinning. Certificate pinning is an operating process that helps with app defense against intermediary attacks that occur on unsecured networks. There are limitations to this process, however, such as lack of support for network detection and response tools. Certain browsers make certificate pinning difficult, making it more difficult for hybrid applications to run.

Minimize application permissions. Permissions allow applications to operate more effectively, but they also open vulnerabilities to cyber attacks. Apps should only be given permission for their key functions, and nothing more, to reduce this risk.

Enhance data security. Data security policies and guidelines should be implemented. Measures such as having well-implemented data encryption, security tools and firewalls can protect information that’s being transferred, for example.

Do not “save” passwords. Some applications allow users to save their passwords for convenience, but if a theft occurs, these passwords offer access to a lot of personal information. If the password is unencrypted, it has a better chance of being stolen. Ultimately, users should never save passwords on mobile apps.

Log out after sessions. Users often forget to log out of an app or website, which can increase the risk of a breach. Apps with sensitive information, such as payment or banking apps, often enforce session logouts after a certain period of time, but it’s important for users to also get in the habit of logging out of all apps when they’re finished using them.

Add multi-factor authentication. Multi-factor authentication adds another layer of security for users on an app. This method can also shore up security for users with weak or old passwords that are easy to breach. With multi-factor authentication, the user receives a code that needs to be entered with the password to log in. The code may be sent through email, the Google Authenticator app, SMS or biometric methods.

3. Analyze Logs for Suspicious Activity

Companies should continuously analyze security logs to identify unusual or suspicious activities, such as logins or application executions that occur outside of usual business hours. These measures not only help identify criminal activities, they can help companies determine the root cause of a breach and how it can be prevented in the future.

4. Keep Systems Patched and Current

Patches identify and correct vulnerabilities in software and applications that may make them susceptible to cyber attacks. All systems and applications should be kept up to date with the latest security patches to prevent hackers and cyber criminals from accessing systems through existing vulnerabilities. Patching and updates may also fix bugs, add new features or increase stability to help the app or software perform better and reduce access points for hackers.

5. Use Strong Passwords and Protect Privileged Accounts

Any password used in your organization should be strong and unique to the account. It’s also important for employees to change their passwords often. Most applications do not alert users to older or weak passwords. Accountability for password protection falls on the user.

If employees have multiple accounts and passwords, companies can create an enterprise password and account vault to manage and secure credentials. Encourage employees to avoid using the same password multiple times.

If employees have local administrator accounts or privileged access, that has a huge impact on organizational security. If a single system or user account is compromised, it can put the entire organization at risk. Your company should continuously audit and identify privileged accounts and applications that require privileged access and remove administrator rights when they’re not needed. You should also adopt two-factor authentication to prevent accounts from being hacked.

6. Do Not Allow Installation of Unapproved or Untrusted Applications

Organizations that allow users to have privileged access also allow these users to install and execute applications as needed, no matter where they source the installation. As a result, ransomware and malware are able to infect your system easily, and the cyber criminal can install tools to permit future access at any time.

Privileged users may read emails, browse sites, click on links or open documents that install malicious tools onto their devices. The criminal now has access and may be able to launch attacks throughout the organization’s system or demand ransom for unlocking proprietary data.

There are security controls that can prevent applications and tools from being installed. They include: Application Allowlisting, Dynamic Listing, Real-Time Privilege Elevation and Application Reputation and Intelligence.

7. Be Deceptive

Whether online or in person, predictability is a boon for criminals. Burglars stake out houses and look for residents with predictable routines, and the same is true of cyber criminals. Automation makes this even easier with scans that are run on a routine, and patches that are implemented on the same day every month, for example.

A predictable company is a vulnerable one, so it is vital to be deceptive. Use random activities and an ad-hoc approach for updates and assessments. With this method, hackers have a more difficult time staying hidden and it’s easier to detect cyber attacks as soon as they occur to mitigate their effects.

Cybercrime is a risk facing all businesses, and the food industry is no exception. Companies that take a proactive approach are in a much stronger position to protect against cyber threats and shore up security. No method is foolproof, but if a breach does occur, identifying it early and mitigating its effects can make a world of difference for your company’s financial health and reputation.