Food and beverage manufacturers face various challenges—including a labor shortage, rising demand and ongoing supply chain disruptions. Food packaging automation can be an essential tool for these businesses, as the technology can improve manufacturing productivity without hiring additional workers.

As demand continues to rise over the next few years, and as the labor shortage continues, packaging automation will likely become more important. This is why manufacturers are turning to the technology and how innovations in Industry 4.0 solutions may reshape food manufacturing this decade.

Food and Beverage Manufacturers Are Doing More With Less

Food manufacturers face the same market challenges that most companies are navigating right now. Even two years after the beginning of the COVID-19 pandemic, the supply chain remains unstable, demand is volatile and job openings continue to outstrip available workers.

Consumer expectations are also changing. A growing segment of American shoppers expects businesses to deliver items faster than ever, putting greater pressure on manufacturers to accelerate production and logistics operations.

These trends aren’t likely to reverse anytime soon, even as the pandemic eases and vaccines become available globally. Some experts predict that the labor shortage may be on track to last for years, and the lack of essential raw materials or components may similarly drag on well into the future. This means hunkering down and attempting to weather current market conditions will not be an effective strategy. Instead, businesses will have to experiment with new ways to improve productivity, reduce operating costs and accelerate delivery times.

Automation may become an essential strategy, especially for food and beverage manufacturing tasks that have traditionally been time-consuming and challenging to automate.

How Food Packaging Automation Helps Manufacturers Stay Competitive

Manufacturers that need to increase factory throughput may struggle to bring on additional labor necessary to improve production. Instead, solutions that help them increase productivity without hiring—like packaging automation—may help companies meet existing demand.

Packaging automation tools allow manufacturers to automate various tasks that are tedious, dull, time-consuming and potentially dangerous.

Industry 4.0 technology also allows packaging solutions to automate work that previously required human labor. For example, AI-powered automation systems can use machine vision—algorithms that enable machines to “see” objects — for quality control and manufacturing purposes. These systems may be able to automatically package items or visually inspect them for defects, allowing businesses to improve quality control processes without the dedication of additional labor.

Food packaging automation can also help make food and beverage products more consistent and safer for workers and consumers. Quality control processes are often tedious or repetitive. Throughout a shift, workers assigned to these tasks tend to slow down and make mistakes, potentially allowing defective or dangerous products to move further along the production line.

Automated packaging systems are remarkably consistent when well-maintained. They can run for hours at a time without the same risks that may come with human workers assigned to tedious or repetitive tasks.

Some internet grocery retailers are also using a combination of AI and RFID to improve package branding and drive sales. RFID allows businesses to embed unique identifiers into the packaging of every product they sell, making it possible to collect deeper information about consumer demands and purchasing habits.

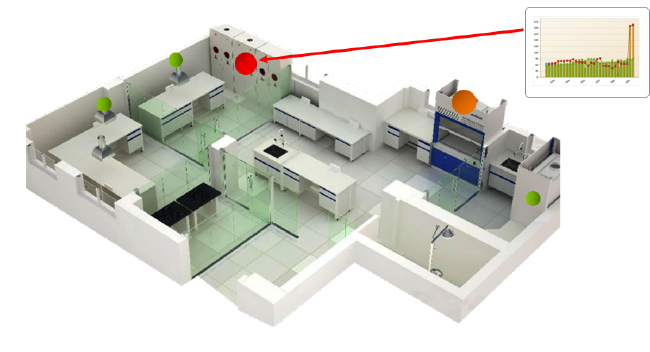

Other AI systems use IoT devices that gather real-time data on equipment operations to streamline or automate maintenance checks. For example, a predictive maintenance approach uses AI forecasting algorithms and IoT data to monitor machines and predict when they will need maintenance. The approach is similar to preventive maintenance but is more effective at keeping machines online. In practice, the forecasting power of a predictive maintenance algorithm can reduce downtime and maintenance costs.

Similar AI technology can also be used in the packaging design process. An AI algorithm trained on a library of packaging data may be used to create new packaging—helping businesses identify novel options when it comes to shape or material choice.

Other Advantages of Packaging Automation

Reducing the cost of packaging can also allow manufacturers to spend more money on higher-quality food wrapping—which can, in turn, improve customer satisfaction and drive revenue. For example, many manufacturers have begun to offer eco-friendly packaging materials that can be customized with branding elements. These packaging materials will attract customers who want to buy products from eco-friendly brands. They will also help manufacturers build deeper client relationships while growing additional company awareness.

Over time, these decisions can help a business transform its packaging into a branding tool. This will require an additional up-front investment, but the improvements will pay for themselves over time.

Packaging Automation Can Help Food and Beverage Manufacturers Adapt

Cutting-edge industry technology has made packaging solutions more effective than ever. The right equipment allows food and beverage manufacturers to automate various packaging, design and maintenance tasks—making individual facilities and businesswide processes much more efficient.