Audits and being prepared, and audit-ready are becoming increasingly important in the food safety world as the industry is moving to compliance with rules proposed under Food Safety Modernization Act. In this Q&A, from a webinar hosted bySafetyChain Software, and SCS Global Services, Heena Patel, SCS Global’s Senior Technical Director and Auditor answers some key questions about audits.

Q: What are the 5 top Best practices to follow for successful audits?

Heena Patel: As an auditor myself, I have conducted hundreds of audits. Auditors look for specific things and can make keen observations. They look for confidence, if the audit team on the site is well prepared for the audit or not. So be prepared for the audit. Be confident, follow the audit plan, have key staff present for the opening and closing meetings and for the facility walk through.

Don’t make the auditor wait for you to locate reports and records. Follow the audit plan; the plan is sent to the site ahead of time for a reason. It has details about the audit and what it would involve, and is a very good guideline that can be used to prepare for the audit by getting ready all the necessary reports and records.

Conduct mock internal audit to prepare for the final audit. Internal audits can help you prepare for any surprises. Use the information for the internal audit to answer questions during the actual audit.

Senior management must be prepared to show commitment and support for the food safety team. This matters a lot to the auditors.

And finally, feed your auditor well. It’s not a good idea to have a grumpy auditor.

Q: What are the biggest ‘No-Nos’ leading to deductions?

Patel: I would list the following items that lead to deductions:

- Lack of management commitment and lack of team work;

- Being unorganized and unprepared;

- Not following and/ or not understanding code requirements; and

- Not fully answering auditors’ questions.

Having incompetent team and incomplete documentation reveals the company not having the necessary training, or professionally trained personnel in-house. Having pre-requisite programs in place is huge in the audit checklist and this covers aspects such as sanitation practices, mock recalls, allergen management, training, testing, etc. We also look for business continuity plans, and management reviews. At SCS Global, we use a matrix with all this information to see what has been addressed well during the audit.

Q: What do auditors look for in demonstrating continuous improvement?

Patel: As an auditor, I love this aspect of an audit. Auditors don’t like to see that the program is not moving forward and is not getting the commitment and resources required from management. They must be focus on investing in employees with training and continuous education programs; and focus on upgrading structures and fixtures throughout the building as needed. Key performance indicators or KPIs must be developed that measure the performance of the food safety and quality program. These must be based on findings of the internal audit, external audit, or recalls etc. It’s also important to trend and evaluate this data during management meetings to see where the program stands and how it can be improved, as part of the continuous improvement program.

Q: How can companies best prepare for unannounced audits?

Patel: Unannounced audits are great from an auditor’s view point, as we can use this to see if the site is truly audit-ready at all times. Often with announced audits, we go in and notice that the floor has been swept well, there are no cobwebs anywhere, everything’s nicely arranged on the shelves etc. But you also realize that the mock recalls has been conducted the day before; the internal audit was conducted two days earlier. And this is not a good sign.

It’s important for food facilities to have a schedule in house in which records based on internal audits/ sanitation programs/ mock recalls etc. can be updated on a continuous basis. The actual audit should just be used to review and sign off on these records.

How can companies be audit ready at all times? By monitoring all programs continuously; keeping the facility clean at all times; and keeping the paperwork up to date at all times.

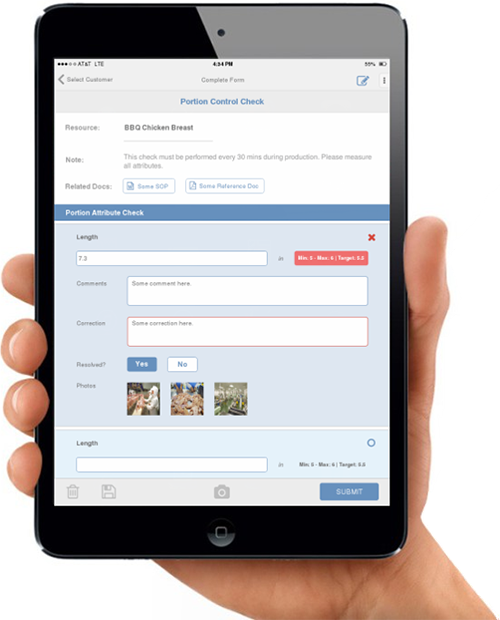

Q: How can automation/ technology facilitate audit readiness?

Patel: Many years ago when I used to audit food facilities, there were no automation systems in place. Auditors were using hard copies and paper checklists. Now, automation has made the entire process more efficient and communication friendly. Automation can help prepare audit plans, schedule tasks and assign food safety personnel to different parts of the program; have a centralized repository for records and data; work with Certified Bodies and suppliers who can all see information in one place; report non-conformances; put in place due dates for suppliers and auditors to either confirm or reject actions; have records on who conducted the audit, all non-conformances, all corrective actions etc. Having automation technology helps save on all the paper work involved in managing a food safety program and preparing for an audit.

To sum up, automation can:

- Provide greater records efficacy;

- Make it easier to communicate with your auditor when on-site and pre-/post audit;

- Incorporate automated reminders to help food safety managers and auditors meet required deadlines; and

- Save time preparing for your audit by automating record keeping.

Get more insights into the auditor’s point of view as Heena Patel answers more questions on this topic. Click here to access the recorded webinar.