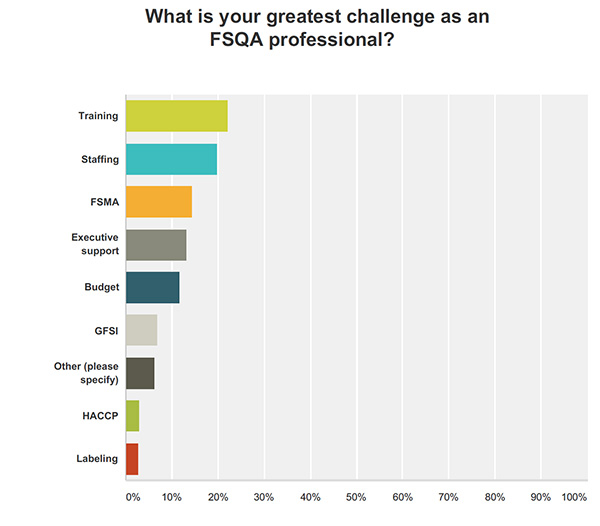

A new industry survey is highlighting several issues facing food safety and quality assurance professionals, from employee retention to understanding the final FSMA rules. The 2016 Annual TraceGains Food Safety & Quality Assurance (FSQA) Professional Survey digs into the top priorities (FSMA compliance, audit readiness, supplier relationship management, etc.) of professionals and sheds light on some of the current challenges that companies are facing, especially in the area of compliance, FSMA readiness and supplier documentation.

“We’re seeing a recipe for stress in the food and beverage industry: Take one-part low margins, blend in one-part increased government regulation, one-part unannounced audits, one-part increasing customer demands, and one-part manual paperwork,” says Gary Nowacki, CEO of TraceGains. “Mix well, bake on high, then spread thinly with a limited pool of FSQA professionals.”

Nearly 500 FSQA professionals participated in the survey. In a two-part Q&A with TraceGains, Anthony Arocha (customer success consultant), Rajan Gupta (vice president of customer success), and Jason Ulrich (customer success manager) explain what the results mean in to the broader industry.

Food Safety Tech: Were there any surprises with this year’s survey?

Anthony Arocha: FSMA compliance is across the board a top priority with staffing/training as one of the biggest obstacles to overcome. I would say this is a huge opportunity for automation to help reduce the risk and long-term costs incurred by the increasing demand for accurate documentation.

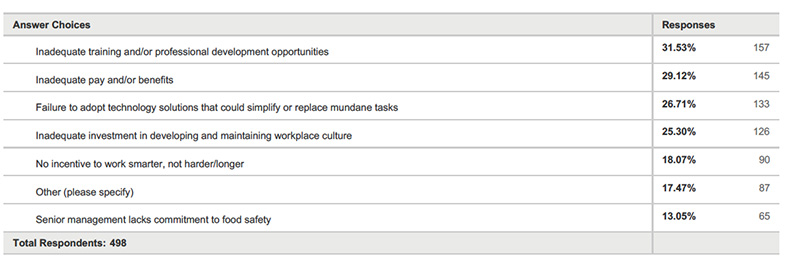

Rajan Gupta: I do not think there are any surprises but a very strong restatement that FSQA staff is difficult to hire/retain due to limited individual growth, low salaries, inadequate training, incentives, etc. All of these lead to the fact that most food companies look at food safety and quality as a nuisance that they must deal with versus as a function that is a necessity or a requirement with adequate funding.

FST: With FSMA being a top priority among survey respondents, are you finding that companies are concerned about any of the rules in particular?

Arocha: Honestly, it seems that most folks are trying very hard to get a handle on all the new rules and what their responsibility is for compliance. Not sure they have gotten to the point of having just one or two main concerns yet. There is more emphasis on creating strong relationships with the downstream and upstream customers and suppliers than ever before. Some of the rules seem vague, which will require an operation to be prepared to support how they meet a particular requirement or may be potentially exempt from it. These have been some of the concerns that seem to be popping up most.

Gupta: The main theme that we hear from our customers is that there is confusion. Companies have had to deal with many requirements in the past, some of which conflict each other. I think lack of a thorough understanding of food safety within an organization is a key limiting factor to truly determine what is needed at each organization to meet FSMA guidelines.

Jason Ulrich: Companies are concerned about FSMA. Most are concerned with FSMA as a whole. Many have taken steps to educate themselves, but the law is vague, especially for companies that are in multiple areas of food manufacturing.

Part two of the discussion will explore supplier documentation and automation.