Most likely, you’re going to do everything in your power to set up a proactive prevention plan to block out this virus. You’d probably want a new policy for inspecting incoming shipments. You’d probably want to add monitoring devices and install automated devices to ensure the virus is blocked out. And, you’d probably start checking the stored products you already have safely tucked away.

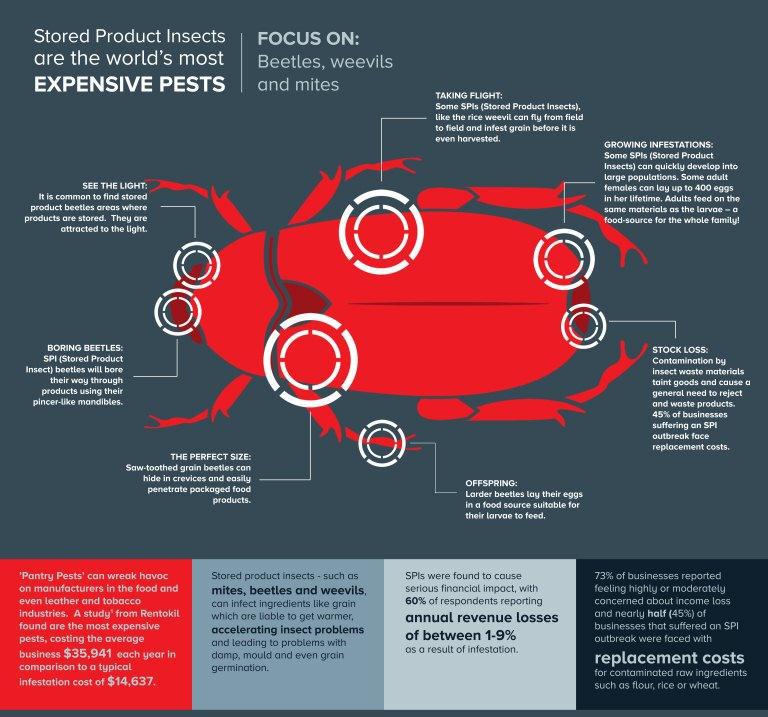

But instead of an imaginary virus, know that beetles can actually do this! Beetles, specifically those that fall into the category of stored product pests, actively seek out and feed on the types of goods that food processing facilities work so hard to protect. While some of these beetles prefer certain types of foods over others (grains are a pest favorite, for example) they’d love to find a home in your facility.

While it may seem like an invisible, pervasive virus is a far cry from some beetles running around your facility, know that this comparison isn’t a stretch. The beetles we’ll look at in this article are all four millimeters long or smaller, so it’s not going to be the type of pest that you happen to notice and can quickly remove. These types of beetles are known for their ability to stealthily invade stored products and feed, reproduce and survive right there in the product. If your first thought is, “well, I’ve never seen one of those,” then you need to inspect your products. And soon.

In fact, one study from the University of Wisconsin and the USDA found that “stored product pests can damage, contaminate, or consume as much as 10% of the total food produced in the U.S. alone, while in developing countries that rate has been estimated at 50% or more.”

Stored product pests are prevalent. And beetles are some of the most common we find in the United States, with multiple different species plaguing food processing and storage facilities. Because the most common species vary from region to region, it often takes the insight of a trained pest management professional to correctly identify one of these pests.

That said, let’s dive in a little deeper on just a few of these beetles to better understand what attracts them and how they operate to get to your stored product.

Cigarette and Drugstore Beetles

Similar in appearance and in their habits, cigarette and drugstore beetles are two common beetles found in food processing facilities. Generally, about two to three millimeters in length, these light brown bugs are tough to spot and a pain to remove if not detected quickly.

Both beetles are known for their ability to chew into stored products and penetrate through some packaging. Once inside, they feed and spread to other nearby food sources over time. And when it comes time to reproduce, both species of beetle will lay eggs directly on or in food products. The larvae then go on to spend most of their young lives thriving while surrounded by a consistent food source until they reach adulthood. At that point, the infestation is going to spread to neighboring products and the population will start to increase at an accelerating rate.

Despite their naming, both beetles eat a variety of foods including cereal, coffee beans, spices, rice, dried fruits, animal-based products and pet food. If there are any small holes in packaging—even cardboard—it’s possible that cigarette or drugstore beetles are present.

Flour Beetles

Reddish-brown in color and about three to four millimeters in length, flour beetles are longer, narrower beetles than the cigarette and drugstore beetles. Flour beetles are so small, it usually takes a magnifying glass to tell the difference between the different species (red and confused).

Another one of the common pests found in stored products, flour beetles can live for nearly a year and deposit hundreds of eggs in that time span. Once they find a way to wriggle themselves into packaging, flour beetles contaminate goods with shed skin and frass (bug poop!). If allowed to feed and thrive for too long, they’ll go from product to product and infest an entire room full of goods. Everything they’ve infested will be unfit to eat and will have to be thrown out, which can prove costly.

The good news (if you can call it that) when it comes to flour beetles is that they’re a bit pickier than other stored product pests. They typically feed on the broken bits and dust from grain that collect in bags of grains, flour, cereal and pasta.

Sawtoothed Grain Beetle

These beetles thrive in the cracks and crevices in foods, wedging their flat bodies through miniscule gaps. Ranging about two to three millimeters in length, these long, thin beetles usually get into products when they’re being transported. Often, the pests are brought indoors unknowingly, where they begin to spread their influence. One tainted item can lead to a massive infestation down the road.

These grain beetles are also known to cause mold problems due to moisture buildup. Frankly, beetle-laden products often wind up having moisture buildup and mold, which can attract other pests to the scene if allowed to persist. In their adult form, sawtoothed grain beetles are known to travel quite a bit, so it’s possible you may spot them on the floor or in cracks and crevices near food storage areas.

The food preference for sawtoothed grain beetles is a little different from the previous two groups of invasive beetles, as they prefer to feed on food items like birdseed, cereal, chocolate, dried fruit, flour, pasta, pet food, nuts, tobacco and yeast.

Proactive IPM and Prevention Tips

Now that we’ve reviewed some of the signs that stored product beetles might be present at your facility, let’s discuss the many things you can do to proactively prevent them.

First and foremost, a variety of tactics should be incorporated as part of your Integrated Pest Management (IPM) program. Under FSMA regulations, this is something every facility should have at this point. It emphasizes a proactive approach to pest management, which is something you’ll need to implement immediately if you want to decrease the risk of a costly pest infestation.

So, let’s look at some specific things you and your pest management professional can implement.

Initially, closely inspect the facility and set up an ongoing plan to inspect incoming shipments for signs of stored product pests like live insects, webbing on products and damaged kernels. FSMA mandates that considerations for your supply chain are in place, so talk to your supply chain partners about inspecting all incoming and outgoing shipments to ensure pest issues can be identified promptly and traced back to the source.

You should also use monitoring devices to help you keep a pulse on pest populations around the facility, which is especially helpful for larger buildings and warehouses. Pheromone traps are especially helpful when monitoring for stored product pests and can help you detect any of the invasive beetle species mentioned previously. Other tools like fly lights and glue traps can help you track other pest trends over time. Once placed, monitoring devices will offer insight as to which areas in your facility are most at-risk for pest problems. Then, you can work on improving the exclusion and sanitation tactics in those areas to reduce the risk of invasive pests.

Also, use temperature as a tactic. These beetles (and other stored product pests) cannot live in extreme temperatures. The fact is that most stored product insects can’t develop below 15o C (60o F). While this isn’t an option for all facilities, even fans and lower humidity can help.

Finally, create a sanitation schedule. This should involve as many staff members as possible and include daily, weekly and monthly duties. Perhaps most importantly, clean up product spills immediately and watch for damp or wet spots that may encourage mold. While it’s impossible to clean up everything, the more you limit the amount and access to food, the lower the chances of insects detecting and pursuing those food sources.

So, be proactive in protecting your stored products from beetles! They’ll prove costly if allowed to destroy and contaminate product, so don’t wait to improve your food safety plan. This threat is worse than an imaginary virus, because it’s very, very real.