As cannabis and CBD edibles and beverages gain in popularity among consumers, the rush to cash-in on market opportunities has resulted in an influx of unregulated and untested products. Recently the FDA increased its scrutiny of cannabis and CBD company websites and social media accounts to make sure they were not making unverified or misleading marketing statements about their products.

To exacerbate the problem of unregulated products, recent scares around vape-related hospitalizations have flooded the news, and the public is looking to the cannabis industry for answers about what it will do to ensure CBD and cannabis products are safe for consumption.

The first step the cannabis business community can take is educating the public on the two types of edibles— tetrahydrocannabinol (THC) and cannabidiol (CBD). THC is heavily regulated. Every batch must be tested before it is released to retail ensuring labeling and dosages are consistent.

Since CBD does not have psychoactive properties, most products do not go through the same testing standards and are far less regulated. An estimated 75% of CBD-only companies do not test their products. Even worse, independent testing has shown that CBD labels are often incorrect or inconsistent with its dosage and ingredient labels.

Both cannabis and CBD companies must advocate for a more regulated and legitimate market. Stricter regulations and testing standards will eventually weed out the bad players who are hoping to make a quick buck from those that intend to manufacture quality products that can benefit the health of consumers.

Short Cuts To Boost Profits

The current vape pen crisis underscores the lack of regulation and inconsistency in the CBD market. CBD-exclusive vapes are more likely to use cutting agents, whereas licensed THC vape companies are more likely to use pure cannabis oils and are required to undergo quality control testing.

Using cutting agents may lower operating costs, but often results in an inferior or dangerous product. Cutting agents also inhibit crystallization in CBD oils and increase the shelf life of a product. The cost of production for pure THC or CBD oil is $5–6 per gram, but a cutting agent can reduce the cost down to $0.10–$2 per gram.

With edibles, untested CBD products can introduce Salmonella or E.coli into the supply chain. This oversight could severely hurt the reputation of growers and manufacturers if a serious outbreak occurred.

Learn more about important regulatory & quality issues in the cannabis space from Cannabis Industry JournalThe Solution Is in Testing

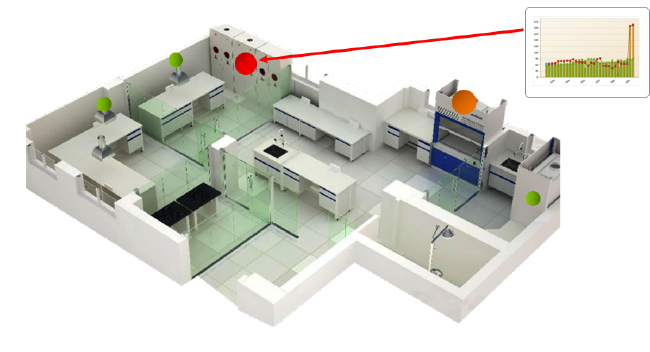

Unlike food manufacturing, where quality controls are in place at the plant, the quality measures for edibles happens in a lab, after a product is manufactured.

Labs test edibles for potency. Both THC and CBD are used for medicinal purposes, and potency testing is critical for accurate dosing. A patient under or over dosing, or taking a poor quality CBD product with additives could detrimentally affect their long-term health.

They will also test for product contamination. Both CBD and THC cannabis can become contaminated with microbes (i.e., mold, mildew, bacteria and yeast), pesticides and heavy metals throughout the process of growing, cultivation and processing. Contamination is especially concerning because many medical marijuana patients are immunosuppressed and cannot fight off potentially dangerous infections and illnesses arising from these contaminants.

But even for the general population, cannabis and CBD contamination can cause serious health issues. Molds and bacteria such as aspergillus, Salmonella and E. coli present safety risks, and toxicity from sustained exposure to heavy metals can lead to high blood pressure, heart issues and kidney failure, among other issues. Fortunately for consumers, cannabis products sold in licensed dispensaries must all undergo contamination and quality control testing per state regulations.

However, because quality control measures are not required for edible manufacturers, there is no oversight that food-grade ingredients are used or that practices to avoid cross-contamination are used.

What Companies Can Do To Win Back Trust

Customers around the country are rightfully concerned about the safety and quality of their cannabis and CBD products in light of recent news surrounding vape-related illnesses. This is the perfect opportunity for manufacturers and consumer brands to seize on the subject and educate consumers about cannabinoids so they aren’t turned off from incorporating CBD into their lifestyles.

- First and foremost, test all products. At a minimum, companies should be adhering to state cannabis market regulations, even if they are just producing CBD. As the FDA rolls out more concrete regulations for CBD, which was only federally legalized last year, it is in the best interest of all CBD companies to meet FDA guidelines preemptively so products can pass inspection at a later date.

- Find a good credible lab to help with formulations and inputs. With edibles and beverages, there is more room to introduce contaminants within that scope.

- Hire food safety experts to help elevate safety standards and meet FDA regulations. Some forward-thinking companies are starting to hire quality experts from food manufacturing to get ready for broader federal acceptance.

- Help educate consumers on why the brand is better, based on inputs and testing.

Consumers should also conduct their own research regarding individual CBD companies’ supply chains and manufacturing standards. Transparent companies will do this proactively, providing cultivation information and lab results for their customers.

In the end, the safest place to buy cannabis and CBD products is a licensed dispensary. It is the responsibility of growers, distributors, manufacturers and retailers to keep the legal market safe and free from contaminants that could threaten the industry. The regulated cannabis space has advanced significantly in the past few years, and companies must set the highest manufacturing standards to maintain this forward momentum. Education and testing are the best solutions to ensure a safe and trusted cannabis marketplace.