I’ve seen it all when it comes to foreign material contamination — from electrical wire to welding slag to a folded-up $50 bill in a block of frozen protein. Physical foreign material contamination isn’t isolated to one type of material, phase of the manufacturing process or point in your supply chain. Physical contaminants can enter food product anywhere, anytime, making reliable detection and actionable traceability vital for producers to ensure safe food to market. We typically trace the issue back to one of three “stops” on a food product’s journey to the end consumer.

Stop 1: Raw Materials

Let’s start from square one: raw materials pose a foreign contamination threat, especially in the case of meat/poultry and fruit/vegetable products. If livestock consume inorganic material like stone or plastic, or metal pieces from plant harvest machinery find their way into plant/organic matter, contamination is immediately a concern. If physical contaminants aren’t detected by a raw ingredient supplier, the risks they pose can be passed downstream in the supply chain to other producers.

Stop 2: Processing

Most raw materials go through an initial stage of processing to turn them into usable ingredients for later-stage producers. This processing stage can involve a higher activity level, leading to more machinery interaction. Perhaps bone debris remains in protein after deboning, or a maintenance failure leads to a lost screw in plant matter. The activity levels at this stage in the supply chain call for increased scrutiny of physical contamination detection and prevention.

Stop 3: Production

Last, these processed ingredients are often turned into prepared or packaged foods. These processes typically include a more refined level of machinery involvement, but also include unique foreign material risks. Machinery, packaging and product breakage are all common challenges at this stage. In the past, we’ve found broken jars, missing pens, lost eyeglasses and more. No producer, no product, no process is immune to this threat—particularly when human beings are involved.

The modern food production environment is highly mechanized, and no matter how new and improved technology may be, the risk of foreign material exists from the machinery used to produce at high throughput. Line extensions, wear and tear, new construction and routine maintenance all play a role in introducing the problem of foreign material in the job of feeding our customers.

Counting the Costs of Foreign Material Contamination

There are many downstream impacts of foreign material contamination. Some are quantifiable, some are not—but all of them hold weight in their own right. Missed orders lead to dissatisfied customers. Storage challenges lead to sunk costs at your facility. Downgraded product leads to lost value and smaller profit margins.

While it’s nearly impossible to sum up the potential effects of foreign material contamination, the image below serves as a point of reference for the many considerations producers have related to this issue.

73% of companies we surveyed in 2024 reported a foreign material incident at least quarterly, many of them citing weekly challenges. Last year, 70 recalls occurred due to foreign material contamination. That frequency is noteworthy, but it doesn’t have to be a crisis. Foreign material contamination can be managed and addressed within any food safety program.

Taking a Closer Look: Technology in Food Inspection

If there’s one thing we know about our industry, it’s that technology is always expanding. More than 50% of food producers use X-ray technology in some form, but there are many other inspection options available:

- Metal Detection. Metal detectors use electric signal disruption to detect metal within a food product. They are of limited use when food contains high moisture, salt, or sugar. They are most effective for aluminum and ferrous metals.

- Vision Systems. These systems use machine learning to “teach” the system but are more often used for qualitative analysis than for foreign material detection, as their examination is only surface-level. Foreign material can and does appear both on and in product.

- Hyperspectral. Hyperspectral systems emit photons of various wavelengths and use spectroscopic sensors to evaluate the energy directed back to identify the material type. While this system type only works at the surface level, it is one of the most reliable detection systems for rubbers and plastics.

- Microwave. While used sparingly in the food and beverage industry, these systems use microwaves and disturbances in the resulting electromagnetic field to detect foreign material. These systems are excellent at detection but haven’t yet reached mass adoption.

- Computed Tomography (CT). CT systems create a 360-degree rotational view of the product, overcoming the positional constraints of a 2D system. Production speeds are too fast for this to work in-line, but these systems are very effective for use off-line.

Embracing technology allows food producers to tailor their contamination prevention and detection strategies to meet their operations’ unique challenges. No matter how physical contaminants are found, once they’re known, the question becomes: What do we do now?

What To Do With a Product Hold

Producers have options to address foreign material contamination incidents. The instinctive reaction may be product disposal, which eliminates the threat of physical contaminants entirely. The ripple effects are lost revenue, potentially damaged retailer relationships and a negative impact to sustainability goals.

In some cases, internal inspection is the best option. Manufacturers use in-house resources and equipment to re-inspect products for contamination, but this option has its limitations. Food manufacturers’ core competency is just that—manufacturing. Plants are equipped, and employees are trained to produce as much food as profitably possible and not to slowly reinspect food, which increases the cost of labor, downtime and overtime.

Third-Party Inspection: A Secret Weapon

Another option exists: third-party inspection. In the majority of cases, a third-party inspection company can find foreign material contamination and limit product loss to only product that is contaminated. This allows companies to recapture revenue that would otherwise be lost at an extremely competitive ROI. It avoids concerns about hidden internal costs of rework, protects brand reputations, protects relationships, ensures manufacturing efficiency, meets or grows sustainability compliance, and upholds product and supplier quality.

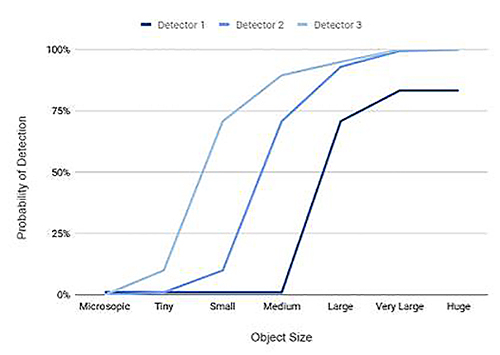

Third-party providers are also typically able to provide data that helps you make the best decisions possible for hold and release—and, in some cases, can provide the data that aids your team in tracking down the issues that are contributing to physical contamination in your supply chain or at your facility. It’s not about scrubbing product clean, it’s about detecting objects at small sizes and providing producers with the opportunity to make better, risk-based decisions.

The two key points of difference between in-house reinspection and third-party inspection are the process and the technology.

Process

- Line Speed: third-party inspection line speeds average 4-5 feet per minute

- Multiple Inspectors: third-party inspection services operate multiple, concurrent inspection lines

- Multiple Facilities: larger third-party inspection services operate multiple facilities across the U.S.

- Trained Inspectors: third-party inspectors are trained specifically to find foreign material, not produce food

Technology

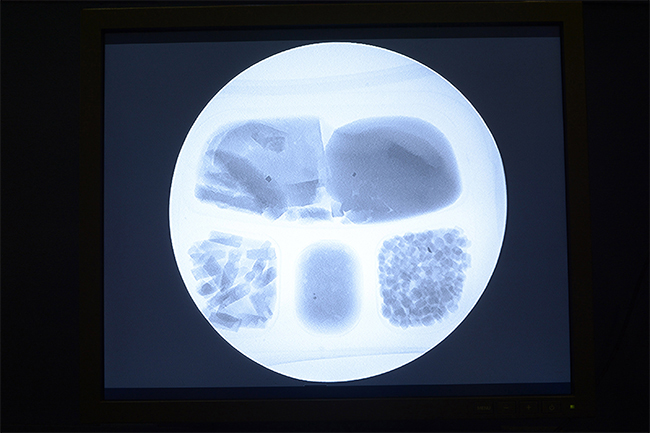

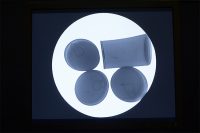

- X-Ray Type: typical inline machines use a linear diode x-ray configuration while leading third-party inspectors use flat panel configurations that enable greater contrast and depth

- X-Ray Size: inline detection technology is typically fixed in place and customized to the product size at a specific stage of production, whereas third-party can inspect product in various sizes and configurations using customized equipment built for that purpose

- X-Ray Sensitivity: inline detection technology is typically built to detect known foreign material types, while third-party technology is designed to detect foreign material of all types

Here’s the bottom line: foreign material contamination isn’t a possibility, it’s a promise. The good news is, producers aren’t powerless. By taking a careful look at their operations, they can determine what tools and methodology will help safeguard their product and their profits, both short and long term.