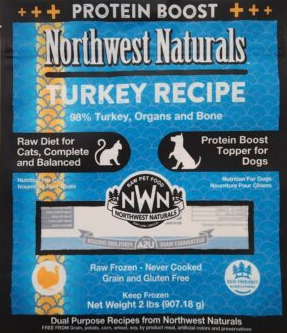

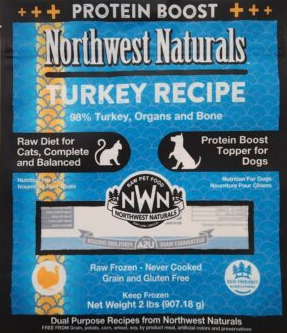

A house cat in Washington County, Oregon contracted H5N1 and died after consuming the raw frozen pet food which lead to the voluntary recall

A house cat in Washington County, Oregon contracted H5N1 and died after consuming the raw frozen pet food which lead to the voluntary recall

Food Defense is a new approach to protecting the food supply chain, and it uses advanced data analytics to better understand and respond to threats. It allows food producers to better understand risks, take the most effective steps to mitigate them, and enable operational and financial efficiencies within their businesses.

To help consumers build nutritious diets, the FDA updated the nutritional requirements a food must meet to use the claim “healthy” on the package.

“This proclamation is a targeted action to ensure government agencies have the resources and flexibility they need to respond quickly to this outbreak. Building on California’s testing and monitoring system — the largest in the nation — we are committed to further protecting public health, supporting our agriculture industry, and ensuring that Californians have access to accurate, up-to-date information.” – Governor Gavin Newsom

This Episode’s theme: FDA’s FSMA 204 Traceability Rule and we’ll explore how the groundbreaking Partnership for Food Traceability (PFT) Watch the Recording

On December 17, 2024, the U.S. Department of Agriculture’s (USDA) Food Safety and Inspection Service (FSIS) announced several new steps to strengthen the agency’s oversight of food processing facilities it regulates (meat, poultry and egg products) and ensure safe food.

Smart packaging can be revolutionary for beverage manufacturers. Packaging technologies like QR codes, RFID, smart sensors and more can create a better customer experience and simplify operations for retailers and logistics. Integrating smart packaging can lead to safer products, less waste and heightened customer engagement.

New Federal Order Will Require National Milk Testing and Support State Officials and Dairy Regulators; Builds on Actions to Protect Farms, Farmworkers and Communities from H5N1 Avian Influenza

The FASTER Act recognizes and highlights the importance of strict quality control, regulating the accurate labeling of products and mitigating cross-contamination in manufacturing and production facilities. With the right technology and systems in place, equipping businesses with the necessary tools, the task at hand becomes significantly more manageable.

The acquisition exemplifies the shared commitment and aligned values of Hygiena and Nexcor, aiming to enhance the safety and operational efficiency of food and beverage facilities through innovative technologies and comprehensive solutions.