I recently sat down with Peter Begg, vice president of quality and food safety at Glanbia Nutritionals where he shared his personal experiences and advice for how to build a career path and grow into a leader. There are a lot of opportunities, and it’s important to remember that a food safety career is not short term—you are in it for the long haul—so don’t be in a hurry, find your own balance, and enjoy life! Have fun! Life is too short to work 24/7.

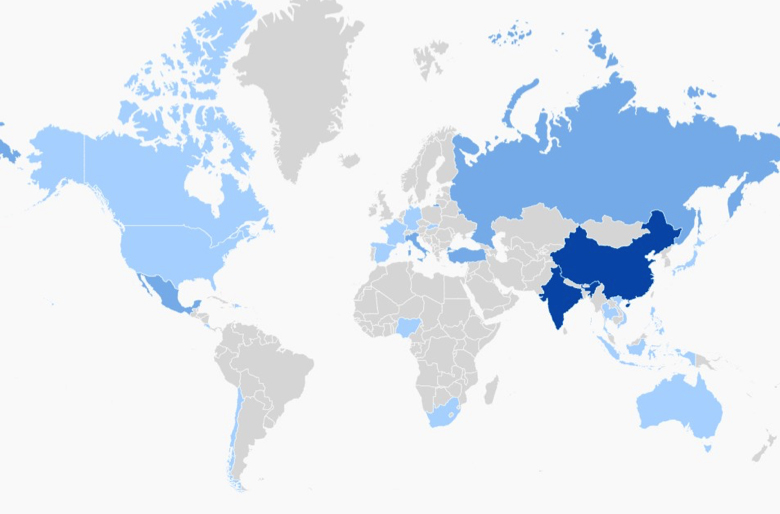

Differing from many food safety professionals, Peter started his career within the food industry as a chemical engineer at Kraft after graduating from Penn State University; now 26 years in the industry, Peter leads a global food safety and quality team at Glanbia Nutritionals. He had a couple of major pivots in his career that led him to where he is today. At the beginning of his career, he joined the R&D department at Kraft Foods, and made the decision to move to Switzerland to take on the company’s European quality team. After three years abroad, he returned to the United States, where he participated in the split of Kraft into Kraft Foods and Mondelez International. Today, in addition to his current role at Glanbia, he also leads the company’s COVID response team. When taking a look back, he affirmed that he made all the right decisions and was glad he didn’t say no to any opportunities that arose.

During the interview, Peter advised young female professionals to be patient and to avoid being in a hurry. Also, find a career path you are passionate about: “When you are passionate, a lot of the challenges or difficulties will pass,” he said. “However, don’t be opposed to trying different roles, especially early in your career. Be open to those other experiences, because they will help you later on.” Additionally, don’t assume that the first experience is going to be the only career path that you will have. Even if you move from R&D to marketing or procurement, that experience will help you. It offers a different way of looking at things. “Nothing you do will be wasted.” I can’t agree more on this point.

When we talked about food science career options for students, Peter had a unique point of explaining the two common options: R&D and Food Safety and Quality. Peter distinguished them by the sense of urgency and challenges of those roles. A project within R&D is normally six months to a year, with timelines to complete the project; whereas within safety and quality, a project could be one day or one week, and is often hard to predict, as every day brings something new. “If you are a person who loves challenges and changes then you might find more achievements in food safety and quality,” he said. “I enjoy the diversity of challenges every day, and this is the reason I didn’t go back to R&D.”

One thing that resonated with me long after the conversation was a tip that Peter would have given to his younger self: “Don’t sweat the small stuff. As you gain more experience, you learn to focus on the things that make the real difference. I know that sounds trite, but you have to get better at triaging and understanding what is important,” he explained.

At the end, Peter pointed out that we still need more diversity in the C-suite and at the SVP level. He learned a lot from his first boss who was a successful female leader. Female leaders are more empathetic and tend to lead without feeling the need to fill airtime. “I have known so many women leaders. They are comfortable in who they are as a leader, and I have a tremendous amount of respect for that,” Peter said.

At the same time, Peter continues to encourage female leaders to be more self-confident. He told us, “Don’t doubt yourself! If you keep getting told ‘no’, it affects your self-confidence, however, it has to be overcome; it takes all of us to remember that we all bring different things to the table.”

Peter shared a couple of personal stories that he found impactful as well. As a leader, Peter cannot emphasize enough about the beauty of diverse thoughts on a team. He learned one can never know everything. As a leader, it’s our responsibility to lead and encourage team members to speak up and grow together; also, always remain calm and solve problems based on facts.

Peter concluded our conversation by emphasizing that we all need to find our own balance to enjoy life. The work/life balance: We work to live, not the other way around. There will be ups and downs. There will be long days, but we can find other days to balance them, and it is important to have an outlet. Life is too short; it needs to be fun—not just work 24/7!

“The real leaders were the ones who spoke to the facts and remained calm and focused on what we needed to do to solve the issues.” – Peter Begg, Glanbia Nutritionals

Melody Ge: What have you learned by working with and mentoring female leaders?

Begg: From a leadership standpoint, my first boss at Kraft was a female and we still keep in touch. She was a great teacher and mentor. There’s an empathy that female leaders have that not all male leaders have. Also, when I made the move to Mondelez and I worked for the head of research & development and quality who is another phenomenal female leader, she had a style about her that kept everyone at ease. She would ask very poignant questions, but she didn’t overuse airtime. I’ve seen men hog all the airtime, because they want everyone to know they are the smartest one in the room. I haven’t seen that with some of the female leaders; they are comfortable in who they are as a leader, and I have a tremendous amount of respect for that.

Right now, I have six directors and four of them are female. To be fair, I think in our function of Quality and Food Safety you do see at least 50% [balance]. For me, it’s the diversity of thought brought to the team. There are different ways of looking at things from men versus women. I think that ability to communicate and be empathetic is something I see out of female leaders. I’ve learned 26 years in that I don’t know everything. Having that diversity of thought and background is absolutely critical to having a strong leadership team and also to make decisions that are well thought through.

To be honest, I think what we are lacking is the diversity at the VP and SVP level and above where it is still pretty male dominated, and that needs to change. I see a lot of strong up-and-coming females; there’s talent out there that I hope continues to grow in the future.

Ge: Why do you think there is a lack of females at the VP and SVP level? Is there any insight you can share?

Begg: One of the reasons is because that, with many leaders, they want people who they can trust. A lot of people look to those who act like themselves. It takes a lot of good thought to take yourself out of that and really look at who is the best leader for your team. I think part of the reason is that many of the CEOs and SVPs are male. We still need more diversity in the C-suite.

Ge: Can you share an unforgettable story that had an impact on you?

Begg: There are two that come to mind.

- I was a very new leader within R&D at the time and leading a cross functional team. One of my team members came up with what I thought was a pretty good idea. I shared it at a meeting, and everyone liked it. But what I failed to do was not recognize the team member whose idea that it was. The team member was really upset and felt like I presented it as my idea. That, of course, wasn’t my intent, but I learned that my job as a leader is to set my team up for success and not get in the way. You also have to give proper credit and acknowledgement. That is something to this day that I keep in the back of my mind—to make sure that I always recognize my team publicly, especially when they are the ones driving the effort. I am not on the frontlines, my team is. I have to make sure that I remember that you need to take the time to acknowledge people.

- When I was in Europe in the quality and food safety role, we had a situation where we were very close to a 27-country recall. It’s something I will never forget because of the intensity of the conversations that were had all the way up to the CEO of Kraft at the time. It ended up that we were able to narrow it and my team did a phenomenal job on tracing the recall down to two countries. What I remember most in that setting, where you’re with all these senior executives, is that the real leaders were the ones who spoke to the facts and remained calm and focused on what we needed to do. The people who I didn’t want to be like were the ones who were emotional and flying off the handle about things that had nothing to do with what we were trying to resolve in the situation. As a leader, you have to project a presence and a sense of calm in a food safety crisis. If you’re in a food safety and quality role, something will happen along the way that is challenging. That is just the nature of what we deal with.

Ge: What would you hope to see in next three to five years for women in the industry?

Begg: Definitely more female outstanding professionals. At Glanbia, we hire 15–20 grads in the U.S. every year through campus recruiting, and it’s at least 50% female. The talent pool is there—but how are we nurturing them, and giving them the support and career guidance? Everyone across the industry needs to have these conversations and talk about the key experiences, key skills and capabilities that they should be building throughout their career. There are certain things that are translatable regardless of the type of job that you have, such as communication skills. Secondly, helping women build the confidence that they can be successful and that there will be opportunities. As a leader, I am part of creating those opportunities and will continue doing so.