Food defense is the effort to protect food from intentional acts of adulteration where there is an intent to cause harm. Like counterterrorism laws for many industries, the IA rule, which established a compliance framework for regulated facilities, requires that these facilities prepare a security plan—in this case, a food defense plan—and conduct a vulnerability assessment (VA) to identify significant vulnerabilities that, if exploited, might cause widescale harm to public health, as defined by the FDA. Lessons learned during the conduct of food defense vulnerability and risk assessments and the preparation of the required food defense plan are detailed throughout this three-part series of articles. Part I of this series addressed the importance of a physical security expert, insider threat detection programs, actionable process steps (APS) and varying approaches to a VA. To further assist facilities with reviewing old or conducting new VAs, Part II will touch on access, subject matter experts, mitigation strategies and community drinking water through more lessons learned from assessments conducted for the largest and most complex global food and beverage facilities.

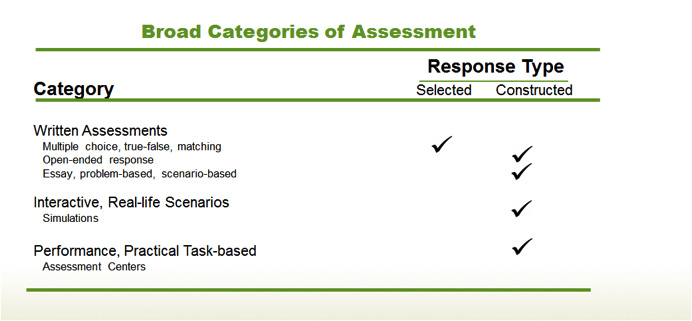

Lesson 6: Utilization of Card Access. The FDA costs of implementing electronic access control, as reported in the Regulatory Impact Analysis document (page 25) are shown in Table 1.

| Average Cost Per Covered Facility | Initial | Recurring | Total Annualized |

| Prohibit after hours key drop deliveries of raw materials | $ | $1070 | $1070 |

| Electronic access controls for employees | $1122 | $82 | $242 |

| Secured storage of finished products | $1999 | $– | $285 |

| Secured storage of raw materials | $3571 | $– | $508 |

| Cameras with video recording in storage rooms | $3144 | $– | $448 |

| Peer monitoring of access to exposed product (not used) | $47 | $1122 | $1129 |

| Physical inspection of cleaned equipment | $– | $303 | $22 |

| Prohibit staff from bringing personal equipment | $157 | $– | $22 |

| Total | $9993 | $1455 | $2878 |

| Table I. Costs of Mitigation | |||

In our opinion, these costs may be underreported by a factor of five or more. A more realistic number for implementing access control at an opening is $5,000 or more depending on whether the wire needs to be run in conduit, which it typically would. While there are wireless devices available, food and beverage organizations should be mindful that the use of wireless devices may in some cases result in the loss of up to 50% of electronic access control benefits. This happens because doors using this approach may not result in monitored-for-alarm conditions, such as when doors are held open too long or are forced open. Some wireless devices may be able to report these conditions, but not always as reliable as hardwired solutions. Using electronic access control without the door position monitoring capability is a mistake. From a cost standpoint, even a wireless access control device would likely be upwards of $2,000 per opening.

Lesson 7: In the interest of time, and in facilities with more complex processes (which increases the work associated with the VA), plan to have quality, food safety and physical security personnel present for the duration of the VA. But also bring in operational specialists to assess each point, step or procedure for the respective operational areas. You may wish to have a quick high-level briefing for each operational group when it’s their turn to deliberate on their portion of the manufacturing operation. Proper planning can get a hybrid style VA done in one-and-a-half to three days maximum for the most complex of operations.

Lesson 8: Conduct a thorough site tour during the assessment process; do not limit your vulnerability activity to a conference room. Both internal and external tours are important in the assessment process by all members of the team. The external tour is needed to evaluate existing measures and identify vulnerabilities by answering questions such as:

- Is the perimeter maintained?

- Are cameras pointed correctly?

- Are doors secure?

- Are vehicles screened?

- Are guards and guard tours effective?

- Internal tours are important to validate documented HACCP points, steps or procedures.A tour also helps to validate process steps that are in multiple parts and may need to be further assessed as a KAT, for public health impact, accessibility and feasibility or to identify issues that have become “invisible” to site employees which might serve a security purpose.

- Properly conducted tours measure the effectiveness of a variety of potential internal controls such as:

- Access control

- Visitor controls

- Use of identification measures

- Use of GMP as a security measure (different colors, access to GMP equipment and clean rooms)

- Effectiveness of buddy systems

- Employee presence

Lesson 9: Do not forget the use of community drinking water in your processes. This is an easy way to introduce a variety of contaminants either in areas where water is being treated on site (even boiler rooms) or where water may sit in a bulk liquid tank with accessibility through ladders and ports. In our experience, water is listed on about half of the HACCP flow charts we assessed in the VA process.

Lesson 10: Some mitigation strategies may exist but may not be worth taking credit for in your food defense plan. Due to the record keeping requirements being modeled after HACCP, monitoring, corrective action and verification records are required for each mitigation strategy associated with an APS. This can often create more work than it is worth or result in a requirement to create a new form or record. Appropriate mitigation strategies should always be included in your food defense plan, but sometimes it produces diminishing returns if VA facilitators try to get too creative with mitigation strategies. Also, it is usually better to be able to modify an existing process or form than having to create a new one.

Lesson 11: In cases of multi-site assessments, teams at one plant may reach a different conclusion than another plant on whether an identical point, set or procedure is an APS. This is not necessarily a problem, as there may be different inherent conditions from one site to the next. However, we strongly suggest that there be a final overall review from a quality control standpoint to analyze such inconsistencies adjudicate accordingly where there is no basis for varying conclusions.

Lesson 12: If there is no person formally responsible for physical security at your site, you may have a potential gap in a critical subject matter area. Physical security measures will make at least a partial contribution to food defense. Over 30 years, we have seen many organizations deploy electronic access control, video surveillance and lock and key control systems ineffectively, which provides a false sense of security and results in unidentified vulnerability. It is as important to select the right physical security measures to deploy, but also critical to administer them in a manner that meets the intended outcome. Most companies do not have the luxury of a full-time security professional, but someone at the plant needs to be provided with a basic level of competency in physical security to optimize your food defense posture. We have developed several online training modules that can help someone who is new to security on key food defense processes and security system administration.

Lesson 13: As companies move into ongoing implementation and execution of the mitigation strategies, it is important to check that your mitigation strategies are working correctly. You will be required to have a monitoring component, correction action and verification intended for compliance assurance. However, one of the most effective programs we recommend for our clients’ food defense and physical security programs is the penetration test. The penetration test is intended to achieve continuous improvement when the program is regularly challenged. The Safe Quality Food (SQF) Institute may agree with this and now requires facilities that are SQF certified to challenge their food defense plan at least once annually. We believe that frequency should be higher. Simple challenge tests can be conducted in 10 minutes or less and provide substantial insight into whether your mitigation strategies are properly working or whether they represent food defense theater. For instance, if a stranger were sent through the plant, how long would it take for employees to recognize and either challenge or report the condition? Another test might include placing a sanitation chemical in the production area at the wrong time. Would employees recognize, remove and investigate that situation? Challenge tests are easy high impact activities; and regardless of the outcome, can be used to raise awareness and reinforce positive behaviors.

Whether training a new security officer, reviewing existing security plans or preparing for an upcoming vulnerability assessment (due July 26, 2020), these lessons learned from experienced security consultants should help to focus efforts and eliminate unnecessary steps at your facility. The final installment in this series will address broad mitigation strategies, the “Three Element” approach and food defense plan unification. Read the final installment of this series on Lessons Learned from Intentional Adulteration Vulnerability Assessments, Part III.