Food and beverage manufacturers are seeing the effects of the coronavirus when it spreads through their workforce. Recently, there have been multiple closures of facilities operated by meat processors, including Smithfield Foods and Tyson Foods as COVID-19 has infected hundreds of workers.

The backdrop of stressful operations and work: Employees now face increased questions before entering plants and feelings of isolation as lunches and breaks are now solo activities due to social distancing. All of these stressors are compounded when you think about what we’re asking them to do: Go into work and keep food on the grocery store shelves. This is a completely new way to operate, and it has a very real emotional effect on our workers.

We’ve received reports from customers where management is getting out of the back office and putting on hairnets to work the production line. The shortage of workers is a very real problem, and our customers are rising to the challenge. Plus, managing this overall labor shortage while doing more safety and sanitation checks than ever before to make sure transmission risks are eliminated is putting stress on everyone working in plants. It’s never been harder to work in the food industry.

In response to California Governor Gavin Newsom’s actions related to the pandemic, we stand behind any effort that is taken to accommodate the needs of these vital, valuable workers, including the executive order to provide supplemental paid sick leave. Such actions, both locally here in California and at the federal level, are critical to elevating the safety of our food manufacturing and distribution workers. Some heroes wear hairnets.

Temp Workers and Lack of Training Protocols

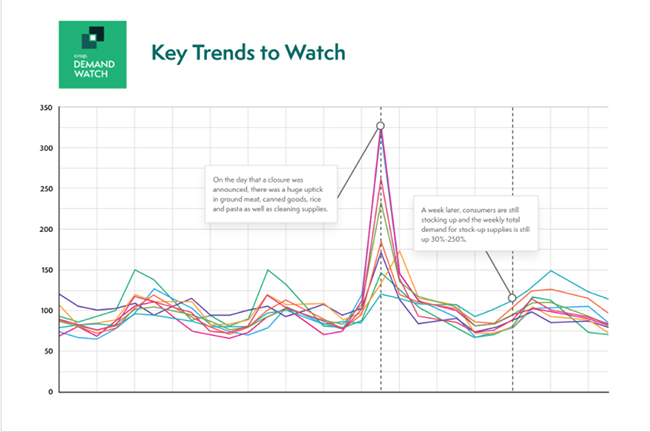

COVID-19 has had a significant impact on the availability of skilled workers in food facilities. Through all the layoffs stemming from the economic standstill, food manufacturers and grocery workers are reporting increases in hiring to help keep up with demand—and to mitigate the effects of sick employees going on quarantine for two weeks. For instance, Albertson’s, a large food grocery chain store, reported that it was hiring for 2,000 positions.

But hiring temporary workers is only half the battle. The task of training people who may have never worked in grocery or food manufacturing has become more critical in the face of new demands on sanitation and social distancing. With these measures in place, it’s no longer a case of a new employee showing up for work and shadowing another employee or supervisor. Technology can close the gap, especially in food production where the regulations and safety standards require strict adherence to processes. For example, software can facilitate shorter employee training in the areas of quality policies and good documentation practices.

Same Volume with Fewer Workers

We are working closely with customers and partners to cope with new guidelines for social distancing inside food facilities, providing the capability to do remote audits as visitor restrictions have increased. Our software is also being used to screen food manufacturing workers for symptoms of COVID-19 before shift work starts to help prevent the spread of the coronavirus to other essential workers.

In response to increased needs from customers, we have developed three solutions to address the impact of COVID-19. These solutions, which include a personnel screener, changeover manager and remote supplier auditor, can help food and beverage manufacturers efficiently manage physical distancing measures, symptom screening, and travel restrictions.

It can’t be stressed enough: The people who carry out food safety protocols are doing more checks and using more labor time to conform to regulations and guidelines for COVID-19. And, adhering to the systems, regulations and processes used to promote safe, high-quality products (in the same or even higher volumes) remains as crucial as ever. Simplifying these processes by leveraging software has been shown to cut 8 to12 hours of labor per day for a single facility. This is critical at a time when even one person being sick can cause lower throughput.

Plus, this isn’t like manufacturing a car where a line will be built to produce hundreds of thousands of cars over a two- to three-year period. Food manufacturers must often change a line over to produce a different flavor, package type or food type altogether, in as little time as possible to keep production going. Robots and automation can help, but in a crisis like this where immediate productivity gains are needed, software can make the much-needed difference.