Months after the most high-profile product recalls in U.S. history, grocery stores are replenishing their supplies of baby formula. While the news remains fresh in everyone’s memory, food manufacturers have an opportunity to reflect on the mistakes that brought about this tragic event.

Abbott Nutrition, which produces about one-fourth of the nation’s infant formula, will be associated with this year’s baby formula shortage for years because it failed on so many levels to keep products safe at its plant in Sturgis, Michigan.

Many of the factors behind this crisis could have been easily avoided or at least quickly corrected. Instead, it took a whistleblower to alert the FDA, citing falsified records, releasing of untested products, sanitation problems, information hidden from auditors, failure to take corrective actions, and traceability issues.

In addition to near irreparable damage to its brand, Abbott Nutrition and members of its executive team are facing regulatory actions, criminal prosecution, and lawsuits.

The formula recall offers an opportunity for food manufacturers to learn from Abbott’s mistakes and to prepare for intensified scrutiny from federal regulators. Let’s dive into some of the most important lessons learned from the Abbott baby formula recall.

Empower Employees

Your frontline employees are your best defense for maintaining food and workplace safety. Make sure they know they won’t face retaliation for reporting incidents. In Abbott’s case, the whistleblower talked about retaliation against employees for reporting food safety concerns. And some employees were afraid they might lose their jobs if they raised concerns.

Take Corrective Actions

A failure to take effective corrective action was a big issue across the board for Abbott and something that all companies find difficult to do. Unfortunately, in the food industry, it’s much more common to put a band-aid on a symptom than conduct a root cause analysis to identify a problem. Fix the root problem as soon as you discover it so you’re not fighting the same fire day after day.

Ensure Record-Keeping Integrity

This seems obvious, but many food manufacturers still don’t have a formalized process to maintain proper record-keeping practices. This process should be documented and shared when necessary with auditors, and there should always be a zero-tolerance policy to prevent falsified records.

Provide Audit Transparency

During the Abbott investigation and audits, there was a lack of transparency and a willingness to withhold information. This can be a fine line to walk. When your workers’ and customers’ health and safety are on the line, it’s critical to be as forthcoming as possible. When preparing for audits, there is the temptation to answer questions only when asked and to avoid volunteering additional information. However, this mentality can mask problems that will eventually come to light.

Establish Proper Sanitation Practices

Many food manufacturers fail to maintain, validate, and consistently implement proper sanitation procedures. Sanitation jobs can be challenging. They involve cold and wet processing environments and are usually worked during third shifts. Most companies struggle with an excessively high employee turnover in these positions. And with few workers on hand, they strive to prepare for the next shift in just a few hours. Maintaining sanitation procedures is a big challenge for many companies, but critical to delivering safe food products.

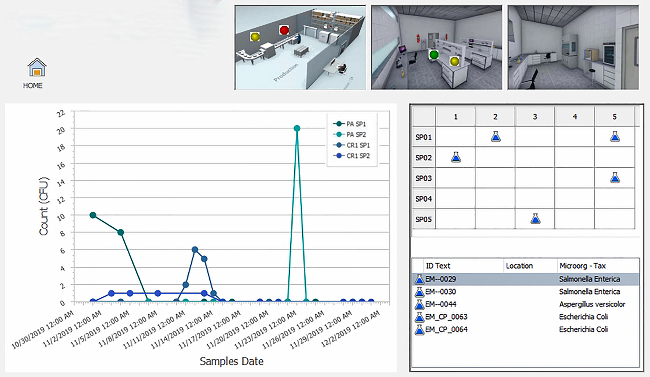

Validate Environmental Monitoring

Food manufacturers should have environmental monitoring programs in place where they test equipment and the processing environment for various pathogens. From food contact surfaces to areas inside the processing room—including floors, walls, and drains—to outside processing areas like break rooms and common hallways, it is imperative to identify the correct sites to sample, ensure adequate sampling frequency, and act when necessary based on the results.

Establish Traceability

Food manufacturers need to be able to trace all raw materials, packaging materials, processing aids, and anything else that goes into their finished product, as well as their shipping processes and destinations. Most companies have a good idea of where products are shipped, but they’re not as adept at tracing the raw materials and processing aids that come into their manufacturing facilities. That was one of the issues cited with Abbott Nutrition, and it’s a problem in the food industry.

Ensure Redundancy and Sustainability in the Supply Chain

Our country relies too much on just a few manufacturers to supply critical food supplies in too many areas. In the case of Abbott Nutrition, one major factory shutdown sent shockwaves through the industry and panicked consumers. Food manufacturers must have backup plans and processes in place in case of recalls, fires, tornados, floods, sabotage, or any other issue that might bring their operations to a halt.

These are some of the most prominent lessons we can all learn from Abbott’s missteps around their baby formula recall. The food industry must do as much as possible to ensure a safe and sustainable food supply. This means evaluating food safety and quality assurance systems to identify potential risks and reassessing programs to create a stronger food safety quality assurance system.

It’s also critical to develop a robust food safety culture across the entire company from the top down. Every manufacturer needs to be proactive in maintaining food safety. No company should rely on inspectors or auditors to discover their issues. They must anticipate questions and problems that can occur during audits through robust internal review processes. This not only allows them to pass their audits but also gives them the ability to proactively identify and address issues before they become major violations or national recalls that make headlines.