In 2017, the cost to import food, which has long been fairly predictable, rose by 6% over the previous year—and the number of possible risk factors has risen right alongside the higher price tag. There are several steps you can take to position yourself as an industry leader and manage risk simultaneously. First, though, it makes sense to better understand what’s at stake.

Why Take Steps to Reduce Risk?

Food has never been a more global market than it is today, and those who operate in the food supply chain are bound by the public’s trust in spoken and unspoken ways. Customers are used to taking for granted that they can walk into a supermarket and walk out with ethically sourced fish and eggs free from E. coli worries.

Not every food product is, or can be, a global one. However, some of these domestic risk factors scale up, just as our businesses do. When the food supply chain crosses borders of any kind, the familiar health and food safety risks are joined by several others:

- Product mislabeling

- Unplanned-for natural disasters

- Spoilage due to any number of unforeseen circumstances

- Damage while in transit

- Unpredictable politics and shifts in regulations

A food company’s supply chain can be the weakest link in their food safety program. Learn more at the Food Safety Supply Chain Conference | June 12–13 | Rockville, MDIn all honesty, no list will ever encompass the scope of the risk you take on as part of the global food supply chain. That’s not to say you can’t take steps to reduce your risk—sometimes several types of risk at once—as your operation grows. The following is a look at several practical suggestions, some of them more time-intensive and perhaps cost-prohibitive than others, but all worth a look as the world grapples with globalization in the food industry.

1. Don’t Take Company Culture or Employee Training for Granted

Working safely and conscientiously in a particular trade is not knowledge we’re born with. When you consider the fact that at some level every food product we bring into our homes was handled at one point by another human being, you get a sense of the role proper training and a healthy culture can play in the safety we expect of our food.

Among recently surveyed manufacturers in the global food space, 77% of them said globalization itself was a source of risk. It’s easy to see why. In 2015, a relatively small—though still deadly—Listeria outbreak was traced to just a few Blue Bell Ice Cream factories. The company was almost ruined by the three deaths, the illnesses and the nearly crushing reputational damage.

Some momentary lapse of judgment at one or perhaps two factories almost killed this company. Now scale this type of risk up to the global level and think about the possible worst-case scenarios.

We’ll talk more in a moment about ways to introduce transparency and traceability to the food supply chain, but this is a reminder of the stakes. Mindfulness and conscientiousness in the work we do— not to mention well-rested and satisfied workers—are just as vitally important to look after as profitability.

2. Use Predictive Sales Forecasts and Intelligent Logistics to Avoid Spoilage

Unnecessary food waste and spoilage emerged as a mainstream issue in recent years all across the globe. For example, citizens in the EU are forced to discard some 89 million tons of food each year due to overstocking, poor quality control and a lack of attention paid to consumer trends. The United States throws out 35 million tons of food for the same reasons—a problem that, billed collectively, carries a price tag of $165 billion each year in the United States alone.

The solution has arrived in the form of predictive analytics and more intelligent warehouse and inventory management systems. Domestic and global supply chain partners alike now have access to, in some cases, highly customizable software systems that can provide vital data, such as:

- Ideal stock levels for perishable items

- Constant checks on incoming versus outgoing products

- Intelligent insights into customer behavior patterns and near-future buying patterns

These types of data are highly actionable. They don’t just shield you from monetary risks by cutting down on waste— they can also protect you from public health risks by ensuring spoiled products never make it as far as store shelves.

3. Take Your Packaging More Seriously

Many of us don’t give packaging a second thought. So long as it’s easy to get into, eye-catching and protects the product long enough for the consumer to get their hands on it, it’s good enough — right? Not quite. When manufacturers think about packaging as merely a branding matter rather than as a safety check, the price is sometimes human health and lives.

One obvious solution to make sure your products can travel as far as they need to is to invest in vacuum packaging, even for small-scale operations. Compressed air equipment is a highly affordable way to accomplish this. The USDA and CDC provide guidelines on modified atmosphere packaging (MAP) and controlled atmosphere packaging (CAP).

Packaging material requirements are a global concern as well as a domestic one. The EU provides guidelines for packaging materials that are detailed down to the type of ink used. Knowing about the laws in your sales territories and staying aware of new breakthroughs in material sciences can help you remain in compliance and ahead of the game.

In a global supply chain, high-quality packaging serves not just as a risk mitigator, but also as a possible value proposition for your customers. Having your brand stand out as an example of high-quality products in thoughtful, health-conscious packaging could put you in a unique position.

4. Stay Abreast of Changing Regulations

American politics might be volatile, but one thing that isn’t likely to change is that consumers tend to look toward institutions like the FDA to provide updated guidelines and to pursue strong, consumer-friendly legislation. That means compliance isn’t always a choice, but it also means you have the opportunity to anticipate change and mitigate risks faster than your peers.

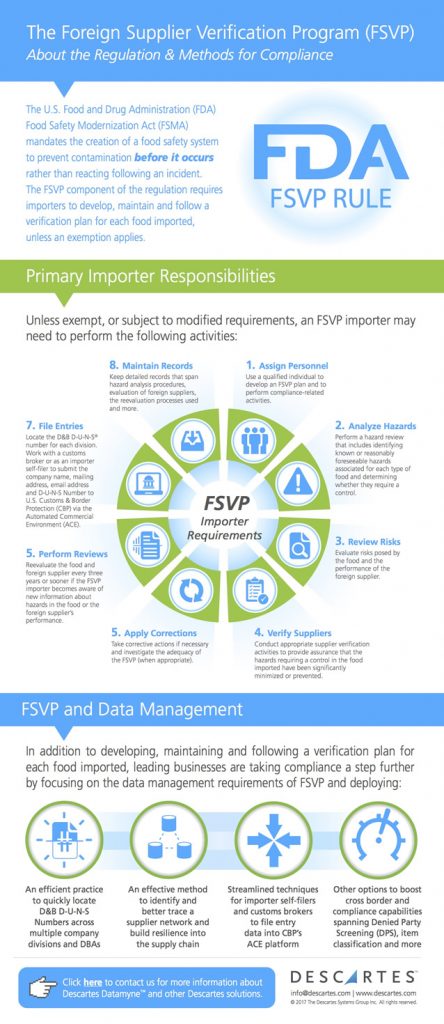

A recent example is FSMA. It’s had a long rollout, with plenty of advance warning for the industries it touches, but now most of its rules have reached the implementation stage. This lead time has been advantageous given the scope of the anticipated laws because it’s given food processing companies time to prepare for compliance. In fact, globalization lies at the very heart of it.

FSMA will be challenging at times to enforce, but its ultimate goal is to hold domestic and foreign companies in the global food supply chain responsible for a common set of guidelines and best practices.

What does this mean? It means you have yet another opportunity to establish yourself as an industry leader. The intentions of FSMA are to make every part of the supply chain more agile and better able to respond to emerging health concerns and other sources of risk as they unfold.

5. Use Data to Build Greater Transparency

There has perhaps never been a more important time to take transparency seriously in the global food supply chain. As of this writing, a historically significant outbreak of E. coli among romaine lettuce products is closing in on an “all clear” from the CDC after two difficult months. By the time you read this article it’s entirely possible another outbreak of a different kind might be underway or that some product or another has found itself under a recall. The possibility of reputational damage is greater than ever.

The good news is, even when the unfortunate happens, it’s possible to greatly reduce risk to your brand and your customers’ health. However, you need the tools to help you move quickly in tracing the problem.

Some digital technologies of a more physical nature, such as QR codes or RFID chips, can elevate your supply chain transparency and tamp down risk even further by allowing far more granular traceability for your products as they move about. In some high-profile examples, we’re seeing this concept taken to a logical, if slightly extreme, endpoint: Edible QR codes on restaurant food that contain a full history of the meal’s constituent ingredients.

Even if you don’t take your own efforts this far, this level of traceability can help you react far more quickly to emerging situations such as recalls. You’ll be able to isolate shipments with greater ease and trace contaminated products back to their sources. Also, as The Guardian points out, this technology delivers ethical and perhaps legal peace of mind by assuring you that your partners are trading in ethically sourced goods.

Vigilance and Technology in the Food Industry

The stakes in the food industry are high, as we’ve seen. However, with the right combination of a cultural approach to safety, a mindfulness of changing regulations and the sensible application of technology so you can act on the data you’re gathering, you’ll be in a prime position for global success in this quickly changing field.