It’s no surprise that food manufacturing and processing environments are naturally vulnerable to food safety threats. Food processing environments have all the things a pest needs to thrive: Food, water and shelter. And if poor sanitation is added to the mix, pests can find your food processing plant absolutely irresistible.

An unkempt facility can attract flies, ants, cockroaches and other unwanted common pests such as rodents. All of these common pests could put you or your facility at risk during your next audit.

The good news is pest-related sanitation issues are preventable through proactive and holistic preventive treatment plans. It’s important to establish proper sanitation processes and procedures so that over time, you avoid or reduce the occurrence of pest problems that could cost you major points on an audit and potentially compromise your products.

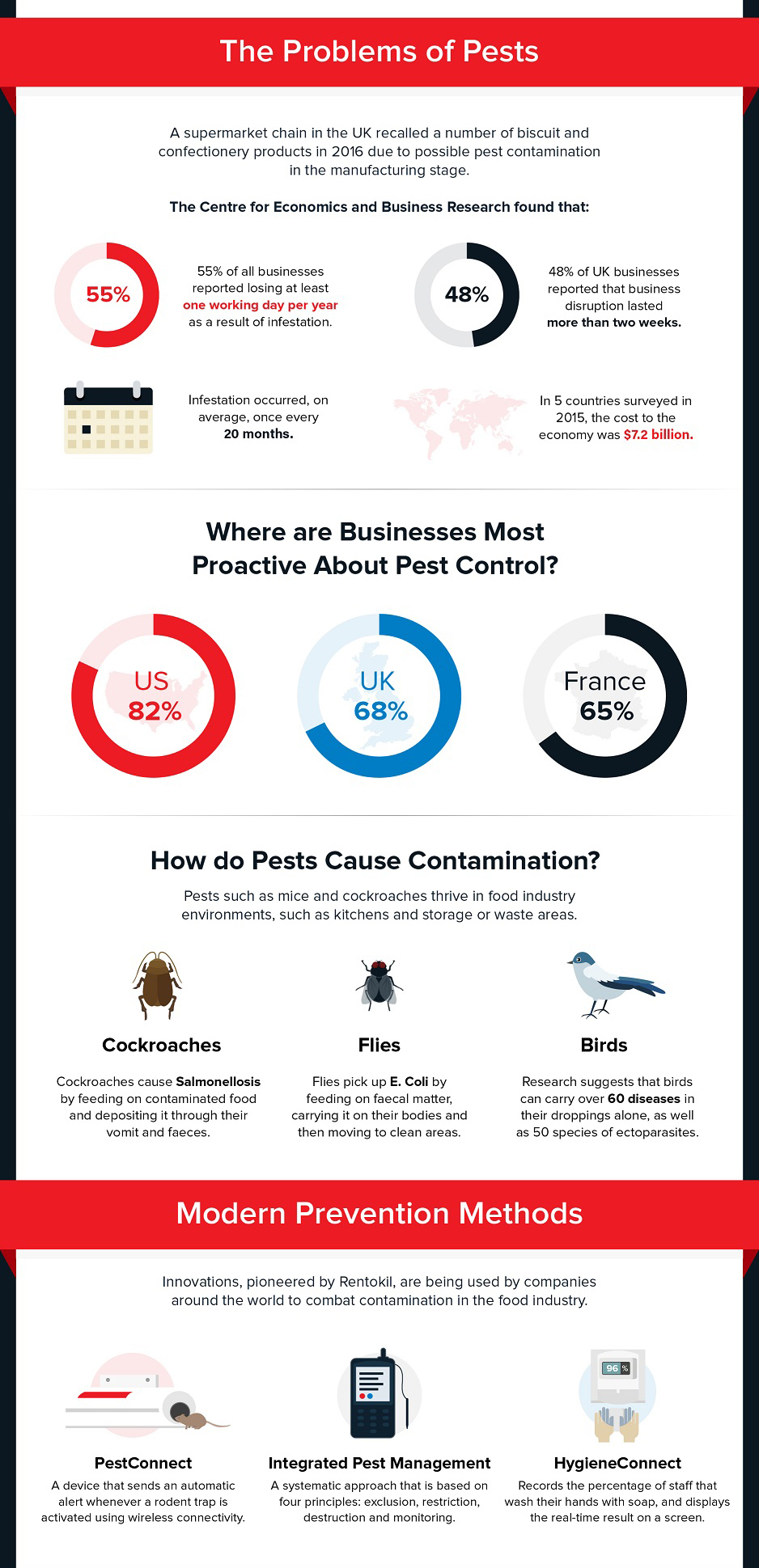

Many food processing facilities employ integrated pest management (IPM), an approach that helps prevent pest activity before it occurs and uses chemical treatments only as a last resort. The goal with these types of treatments is to give facility managers tools to use in advance of their next audit to stay ahead of pests, to teach employees good practices and to avoid problems before they happen. A good IPM program includes careful documentation of pest issues and the conducive conditions relating to them, as well as any corrective actions taken to resolve them. This documentation is incredibly important not just in solving pest problems, but also in its relevance to FSMA regulations.

When talking to pest management providers, remember that a “one-size fits all” strategy often doesn’t work, so expect your pest control company to recommend a customized plan. Different environments have different “hot spots” (areas where pests typically are present if the conditions are right) and face different pest pressures. However, there are a few key best practices that can be applied to any facility to help protect against pests.

The following guidelines will help to minimize pest activity and prepare for your facility’s next audit.

1. Educate and Enlist Your Employees in the Fight Against Pests

The first step to establishing your sanitation plan is enlisting your staff. One of the strongest building blocks in your defense against pest activity is sanitation. This key component of your IPM plan begins with the vigilance of your employees. Sanitation and pest management aren’t one-and-done tasks. They’re ongoing and you’ll get the best results when the entire staff is on board.

How can they help? Your employees are often the first to notice any potential signs of existing problems, so it’s important to educate them on hot spots where pests could live, what signs they should look for, and what to do if they see a pest issue. Once your employees understand the importance of sanitation, set a zero-tolerance policy for spills, debris and waste. If employees spot a pest, make sure they understand the protocols for documenting its presence. Consider implementing daily, weekly and monthly sanitation routines in addition to an annual deep cleaning.

Finally, enlist your employees to help keep common areas clean, from break rooms to locker rooms. Establish processes to clean up dirty dishes and drink spills, and empty full trash bins immediately. Don’t forget about cleaning the bins themselves! Also, make sure that common refrigerators aren’t filled with past-expiration lunches or snacks. If you’re finding it tough to get employees to participate, most pest management providers will offer a free education program to make employees aware of potential risks and what they can do to help. Sometimes it can help employees to hear from the experts.

2. What’s on the Inside Counts

As the saying goes, what’s on the inside really matters. This is true for the interior sanitation of your processing facility, too. There are a few particularly vulnerable hotspots to be conscious of when putting together your sanitation plan, especially the production floor, the storage areas and the receiving areas.

For obvious reasons, the production floor is one of the most important areas of focus for your sanitation program. Any hygiene issue could directly impact and expose your food products to contamination. Pests love to make their homes in big equipment that is often difficult to access for cleaning. Improper sanitation may lead to bacteria growth on the production line, which poses a major food safety threat. Create a schedule so that all equipment and machinery are sanitized regularly, and don’t forget about paying extra attention to those out-of-sight areas.

Drain flies and other pests live around drains and drain lids. Both should be scrubbed and sanitized regularly to prevent buildup of grease and other gunk that can attract pests. Organic, professional cleaning solutions are a great option to break down tough stains and grime on floors and around drains. These organic cleaners use naturally occurring enzymes and beneficial bacteria to degrade stains, grime and other organic matter build up, which helps reduce the likelihood of drain flies and other pests.

Storage areas are also prone to attracting pests and the potential bacteria they harbor. These cluttered spaces can get filled with extra boxes and other debris, and are perfect locations for pests to hide. Keep these areas clean and clear of clutter so pests have fewer areas to seek shelter and reproduce.

Cockroaches especially love cardboard boxes, so take those to recycling facilities regularly. Remove any equipment that is not being used. If you have re-sealable containers, clean out all the containers before placing new products inside. All containers should be tightly sealed and kept six inches off the floor and 18 inches away from walls. You can also affix mops and other types of cleaning equipment to the wall. Keeping them off the ground will keep them dry and prevent them from sitting in standing water, which is a major hot spot for fly breeding and bacteria build up.

Don’t forget that pests are experts at squeezing under receiving doors and sneaking onto shipments. To prevent unwanted stowaways, ensure your exterior doors form a tight seal when closed and always give delivery trucks and incoming shipments a thorough inspection for pest activity. Pests love to sneak into any opening they can find, so keep building exits, loading docks and other entrances closed as much as possible. Install weather stripping and door sweeps to keep pests out by creating a tight seal around openings. Believe it or not, rats can squeeze through a hole the size of a quarter, mice through a gap the size of a dime, and crawling insect pests through spaces barely noticeable to the human eye. For other cracks and crevices, use weather-resistant sealants to close any openings and consider installing metal mesh for an extra layer of protection against rodents that can gnaw openings to get inside.

3. Don’t Forget the Great Outdoors

To keep your exterior spic and span, create and maintain a regular sanitation schedule for your building’s exterior so it doesn’t become a haven for pests.

Regular pressure washings of sidewalks and walls will knock away any debris or build-up on exterior surfaces and could help remove any bird droppings around the property that could be brought inside by foot traffic. While it seems like a no-brainer, keep dumpsters and recycling collections as far away from facilities as possible, and make sure they are cleaned and sanitized frequently. And like interior cleaning best practices, don’t neglect areas above or out of the line of sight like gutters and rooftop ledges. Sometimes, leaves, standing water and other debris can build up over time, which provides breeding areas and shelter for pests—especially mosquitoes.

Did you know that flies are not just attracted to food processing facilities because of food smells, but also for their exterior lighting? Flies and other flying insects are attracted to light and may use it for orientation. Mercury-vapor lighting is especially attractive to flies, so consider swapping mercury-vapor lamps next to entryways with sodium-vapor lights or LEDs. And to lure flies away from your building, place your facility’s mercury-vapor lighting at least 100 feet from entrances. It is often important to remember that the best option is always to direct lighting towards a building rather than mount lighting on it.

Good outdoor pest maintenance also includes landscaping. Trim your trees often and keep plants at least 12 inches away from your building. This decreases the chance of pests using vegetation as breeding or nesting grounds and the chances they’ll get access to your facility. Standing water often becomes a breeding site and moisture source that could provide pests like flies, mosquitoes and rodents with water necessary for survival. Remove any standing water around your building to prevent this and remove any reason for those pests to stick around. Look for stagnant water in gutters, ponds, birdbaths, water fountains and any other places that water could sit for more than a week without moving.

These proactive pest management tips will be useful in protecting your building and products from food safety threats. If there are any tasks that require additional help, consider talking to your pest management provider about creating an IPM plan. They will walk through your facility with you to identify any hotspots and suggest potential corrective actions—you’ll be glad you did when it’s time for your next audit.