Many foods, from honey to olive oil to spices, fall victim to fraudsters each year. Often a time-consuming process, conducting research about each product or ingredient can involve combing through many websites and databases for information. To save companies from doing all that heavy lifting, newer tools are aggregating the data into single platforms. One most recent example is the World Factbook of Food, developed by the Food Protection and Defense Institute (FPDI) and funded by the U.S. Department of Homeland Security. The tool was released earlier this year, and Erin Mann, project manager at FPDI, explains how it is helping food companies mitigate the risk of food fraud in their supply chain.

Food Safety Tech: What are the fundamental advantages of using the World Factbook of Food and how is it different from other tools that companies can use to assess their risk?

Erin Mann: The World Factbook of Food is a central reference location for data related for food. It pulls together a lot of high quality data points from a lot of different sources into a single tool.

Companies can look for information on a lot of different food products and a lot of different sourcing regions and countries. We have more than 125 food profiles (and growing) and more than 75 country profiles (also growing). [There are 10 food profiles and 10 country profiles that are available for free] Each of the profiles covers a large number of topics. On the food profile side, there are data points on how the product is used, codes, information about standards and grades; and a lot of data about trends and consumption, production and trade patterns; there’s information about processing and supply chain characteristics; and another section about food defense and food safety.

It’s a resource that can be used anytime a company needs to get up to speed quickly on a product, because it covers a lot of different types of risks. If a company wanted access to information related to risk about past economically motivated adulteration (EMA) or intentional adulteration (IA) incidents, the Factbook has that. There’s also data on past recalls, information about major producing countries around the world—a wealth of information in one place that companies can use broadly for risk assessment—basically any use case where they want access to a lot of information from lots of sources, the Factbook can be a great place for that.

FST: Can you expand on the food defense component of the Factbook?

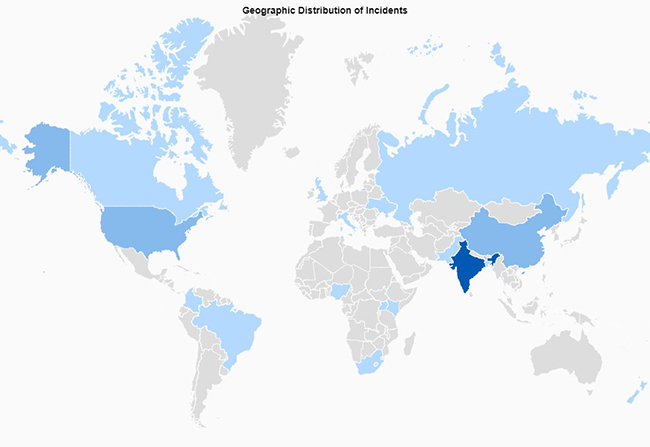

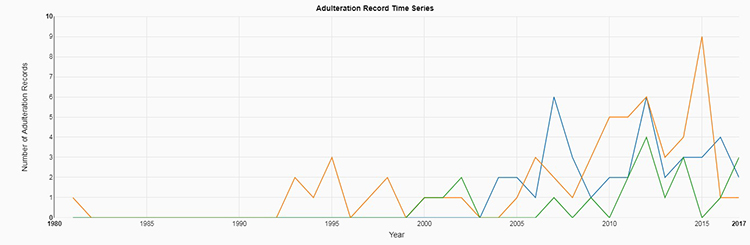

Mann: One of the primary sources that we pull for the food defense section comes from a complementary tool that we use here at FPDI—our food adulteration incidence registry, called the FAIR tool, which is a database of past EMA and IA incidents. On the technology side, the Factbook is directly linked with the FAIR tool. If you’re looking at a profile for a particular product, it will access the FAIR tool and display relevant incidents for that product. It won’t give you access to the entire FAIR database, but it will give you a high-level summary of what food defense incidents have happened in the past with the product, where they happened, the year and a summary.

What we’ve seen with the FAIR tool is high incidents of food adulteration in products like oils, spices, seafood—those are the major products impacted by food adulteration, particularly EMA.

FST: From what sources are the data curated?

Mann: There’s a source list at the bottom of each profile and all the data points are referenced throughout. In terms of a high-level description of where we pull data from, it includes the USDA, FDA, Codex, the U.S. International Trade commission, United Nations data, and other industry and trade groups. It also pulls data from the World Bank and the FAIR tool.

|

Sponsored Content TraceGains’ latest eBook, An Organic State of Mind, sheds light on the trends and demands that are shaping the organic industry today and how automation technology is changing the game for many organic food manufacturers and producers. |

FST: How can companies use the Factbook as part of their overall risk mitigation process?

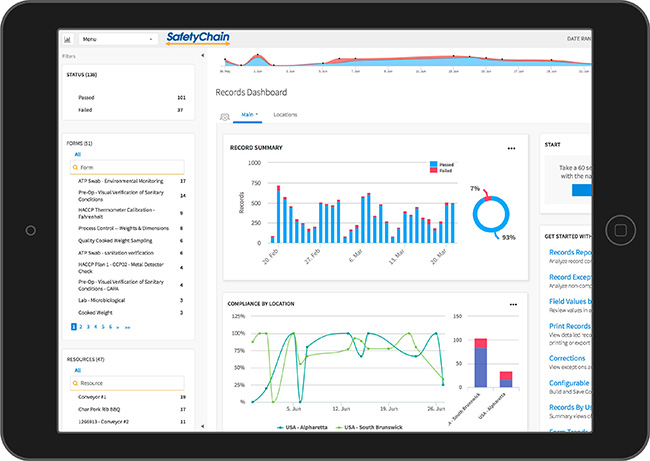

Mann: One of primary strengths of the Factbook is that companies can use it in many different ways. Our institute has done a lot of work with big data and using multiple data sources, and one of the biggest takeaways we learned through several years in this field is that whenever you use big data or you use lots of data sources, they must produce intelligence and information that is actionable. All of the data and information doesn’t do much good if there’s not a clear summary of what to do with that information.

The Factbook aims to do that. It’s a collection and synthesis of data and clean information that’s in an easy to use and easy to navigate user interface. From there, companies can take a look and see how to use the Factbook where they see a gap in their processes. It’s a great place to access lots of information about a food product in a single place. If we can see several points in an overall risk mitigation process where the Factbook can be used, it could be used to inform decisions related to procurement. [For example], if a company suddenly needed to procure a product from a new source region or if they were developing a new product and had to procure an ingredient that they hadn’t worked with before, the Factbook would be a great place to get smart quickly on that ingredient.

The Factbook could be used for understanding supplier review and specific risks related to that ingredient, or simply horizon scanning—if companies want to take a look at some of the products they’ve determined to be high risk and learn more about the product from a holistic perspective.

As stated in the Q&A, 10 food profiles and 10 country profiles are available for free. Subscribers to the World Factbook of Food pay $600 annually for full access to the tool, and bundled pricing is available for users who are interested in access to both the Factbook and the FAIR tool.