As food companies analyze and modify their production processes to ensure FSMA compliance, many are finding that traditional food processing technologies aren’t ideally suiting their needs. Conventional pasteurization technologies like heat pasteurization have been relied on to protect the safety of the food supply over the years, but they aren’t without their downsides. For example, sometimes they negatively impact the flavor, texture, nutrients and color of food products. Additionally, many traditional food processing methods require chemical additives to be integrated to preserve quality and taste. In a market where consumers are more frequently appreciating, if not demanding, cleaner labels with simple ingredients, these solutions are often becoming less attractive options for some companies.

This new demand for a higher level of food safety combined with an emphasis on food quality has led some producers of refrigerated foods to turn to an increasingly popular alternative: High pressure processing.

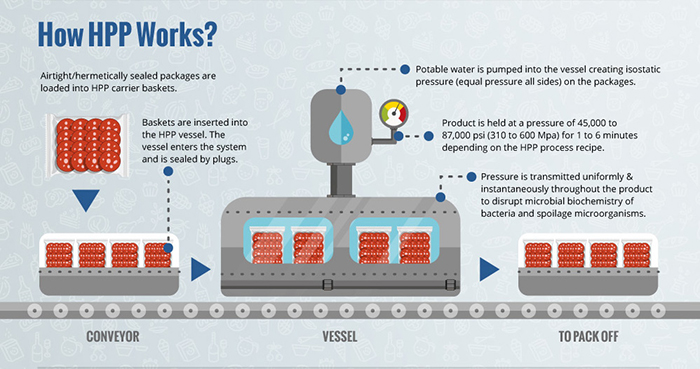

How HPP Works

High pressure processing, or HPP, is an effective technique that uses pressure rather than heat or chemicals to disable pathogens in food. After packaging, food products composed of some degree of water activity (Aw) are placed into a machine that applies incredibly intense water pressure to food—sometimes as much as 87,000 psi.

This process interrupts the cellular function of the microorganisms both on the surface and deep within the food and can serve as a critical control point (CCP) in a HACCP program. Research studies on a wide range of refrigerated food products and categories confirm that HPP technology inactivates vegetative bacteria like Listeria monocytogenes, Salmonella, E. coli 0157:H7, and Campylobacter as well as yeasts and molds. Additionally, because pressure is applied after the food is packaged, HPP drastically reduces any chance of recontamination.

Besides its food safety benefits, HPP offers food producers added benefits over traditional methods. Because the pressure inactivates spoilage organisms along with pathogens, many foods see a substantial increase in shelf life after undergoing HPP, sometimes even twice as long. Processors use this shelf-life extension to increase their distribution reach and reduce food waste.

In a recent survey, 57% of respondents in the food and beverage industry characterized their companies’ use of HPP as substantial or growing. Survey respondents also scored HPP’s ability to make food safer by eliminating pathogens above a 4 on a 5-point scale, one of the highest of any food processing technology.

However, HPP isn’t right for every product. It isn’t effective on some enzymes and bacterial spores, like Clostridium botulinum. Producers need to tap into other techniques to address concerns not affected by HPP. The process also requires foods to be packaged in fairly flexible packaging to allow for an even application of pressure. Glass bottles or particularly hard plastics will not be suitable.

HPP can also be daunting to implement for some companies. Purchasing an HPP machine is a major investment, typically seven-figures, without factoring in specific facility requirements or staffing needs. In the same survey of food and beverage producers, the most commonly cited concerns had nothing to do with the efficacy or value of the technology, but rather with the cost of purchasing and staffing the equipment.

For businesses that don’t want to make that kind of capital expenditure commitment but want to take advantage of high pressure processing, HPP outsourcing providers offer a more affordable solution. These companies own and operate HPP machines on behalf of clients. That way, food brands don’t have to purchase expensive HPP machines and regularly maintain their own equipment.

Is HPP right for you? The answer and the nuances are highly variable, but HPP is a fast-growing food preservation technology offering many benefits, including food safety benefits, across a broad product spectrum.

There is a restaurant in Maryland making dry cured pork, beef and fermented dry sausages. The processes are traditional but not up to FSIS standards for Salmonella.

Their products are excellent and other restaurants have asked to buy them — thus, their wish to come under FSIS inspection.

One option I’ve suggested is a mild heat treatment such as that Tino Genigeorgis recommended. That has been rejected.

Another option is HPP of the finished product.

What would be the cost to HPP small batches of cured pork in you Pennsylvania establishment?

Heat treatment works, but hurts the flavor of the products. HPP works well, but validation is needed, and that can get expensive, on top of the cost of the transportation and processing at an HPP facility. There are alternatives to heat treatment and HPP that will satisfy FSIS. I know several small processors who have done it. I’ll be happy to elaborate, You can call me at 973-342-1143 for a friendly chat (no cost or obligation!)

François Baumont

FBC-Consultants to the Food Industry

We would like to talk with you directly so we can better understand your product specifications in order to provide you an accurate price. Please call me at 404-640-4914. Thank you for your interest.

Respectfully,

Bill

Bill Cook

VP Sales