Your next audit is already on its way. Now that many regulatory bodies and certification agencies are no longer required to give you a heads-up about upcoming audits, it’s completely up to you to stay on top of compliance, recordkeeping, and a myriad of other tasks on a day-to-day basis. And without that buffer of warning from auditors, falling behind can be more detrimental than ever.

Let’s walk through some effective practices that keep you ready for an audit at a moment’s notice, make the process go smoothly once the auditor arrives, and get rid of some unnecessary stress all along the way.

Connect All Departments to an Online Database

When it comes to collecting and moving data from one department to another, there’s nothing as inefficient as disconnected documents. Not only are they a strain to keep organized in big filing cabinets or file folders, but they take a long time to create, share and edit. It seems cliche to harp on this point in 2018; yet, many food safety coordinators have a purely manual system.

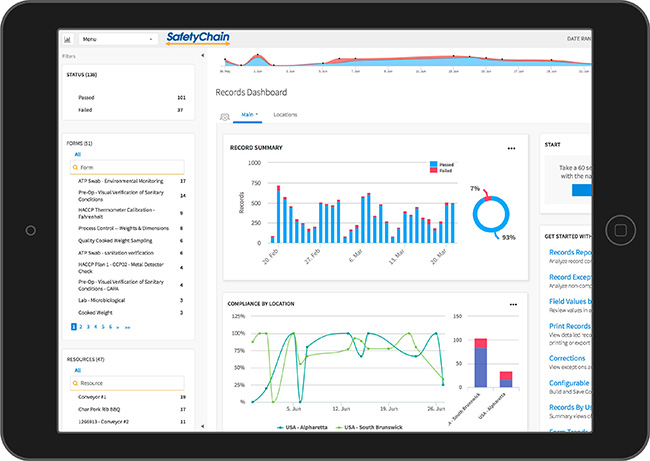

By connecting your entire company to an online database, you enable different departments to organize, share and update documents in seconds, rather than minutes. This level of connectivity can shave time off dozens of tasks per day, which ultimately leads to hours or days of extra productivity over the course of a year. When you adopt a system that updates connected documents in real time, you won’t have to make manual changes to multiple documents for small changes.

If you want to get extra efficient, the real trick to this best practice is to find software that you can incorporate into every department. Then, as people go about their normal jobs, the information they collect is automatically uploaded to the central database.

Utilize the Internet Of Things to Streamline Data Collection

These days, it’s possible to connect almost every piece of equipment to the Internet of Things. Even if your machinery doesn’t have measurement tools built-in, there are almost certainly additional tools you can install to create that functionality.

Having your equipment feed data directly into your central database is faster than manually collecting information and eliminates the risk of human error when it comes to data entry. Thanks to that simple degree of automation, already standard in large parts of the global economy, you can also use system dashboards and alerts that let you know when something’s off, like the temperature in the freezer or the production speed of equipment on the floor.

Don’t Settle for Uninspired Internal Audits

Many food safety coordinators are so focused on specific issues that they forget to take steps back to look at the situation from a bird’s eye view. When the time for an internal audit comes around, they do it with one eye on the audit and one eye on the next fire that needs putting out.

Lazy internal audits are not only noticeable to external auditors, they keep you in the dark about what’s really happening in your facility. Here are a few ways you can ensure your internal audit empowers you rather than slows you down:

- Schedule the internal audit ahead and make it immovable

- Plan out your scope, objectives and process to establish momentum and direction

- Dedicate your full attention to running the audit and managing relevant staff

- Report your findings in detail and discuss with necessary employees

- Schedule and verify corrective actions

A well-performed internal audit is a powerful way to regroup, refresh goals and stay on track.

Train All Employees for Go-Time

Do you know which employees an auditor is allowed to interview? Any of them. No person is disqualified from interviews, which means every employee needs to be well trained on food safety procedures. While most facilities only train employees until they know the basics of food safety for their department, going above and beyond here can have some major gains.

Consider the perspective of the auditor. When they are asking your employees questions, they’re not just trying to complete a basic inspection. They want to see signs that you haven’t done the bare minimum, but that your employees are immersed in a food safety culture, that they have been receiving training long-term, and that food safety is a fundamental value of your company.

When auditors get the sense that your employees are up-to-speed, things tend to go a little smoother, stress levels lower, and the auditor becomes less suspicious.

Give Food Safety Coordinators the Appropriate Authority (and Budget)

One issue that many facilities run into is an unempowered food safety coordinator. When that person discovers ways to improve or correct operations or employees that are not following protocol, he or she is often unable to take the appropriate action.

Hazards aren’t the only things that need corrective actions from time to time. Sometimes employees need to face consequences for compromising the production area with food or for haphazardly completing safety-related tasks. Other times, employees don’t have the necessary software or equipment to perform their job well and even though their managers may be aware, they don’t allocate the appropriate budget to improve the situation. In order for any company to thrive, standards must be enforced by relevant leaders; and there’s no one better to call the shots on food safety than the designated coordinator.

Establish a Company-Wide Food Safety Culture

When it comes down to it, companies that value food safety thrive. Companies that consider food safety an annoying task to check off the list—they’re the ones that run into extra trouble.

Building food safety into your company’s system of values starts at the very beginning with how you train your new hires. It continues on into how you provide ongoing training even to experienced employees. It’s not an item on the list of meeting topics; it’s a value that underscores the entire agenda.

In order for this approach to be successful, it has to start at the top. Facility owners and managers that value food safety will organically pass that on to the people below them. But when the upper levels can’t be bothered with food safety, the entire organization struggles to hold onto it as a value.

Some of these best practices you can start working on tomorrow; others will take time to implement. Embedding these into your company can be a long road, so keep your eye on the prize: A safe, efficient food safety program that impresses auditors and keeps things running smoothly.