Energy usage has increased worldwide, especially with everyone isolated due to COVID-19. That translates to higher costs across most sectors. The Energy Information Agency (EIA) expects U.S. electricity consumption to grow by 2.1% this year.

Coupled with the rising adoption of renewable energy and green initiatives, it makes sense to cut down on electricity consumption as much as possible. Commercial operations, food manufacturers included, could stand to benefit from reduced energy usage.

The question isn’t necessarily “why,” but “how.” What can food manufacturers and similar commercial providers do to reduce electricity requirements? What are some ways to minimize consumption and achieve efficient food production processes?

1. Energy Audits

Process and energy audits are a must. How could one hope to improve a system without understanding everything there is to know about it? More specifically, how could a company reduce energy consumption if they don’t know where, when and how it’s being used? That’s why energy and resource audits are crucial to optimization. It doesn’t matter whether they are conducted in-house or by a third party. What’s important is that they are accurate and detailed.

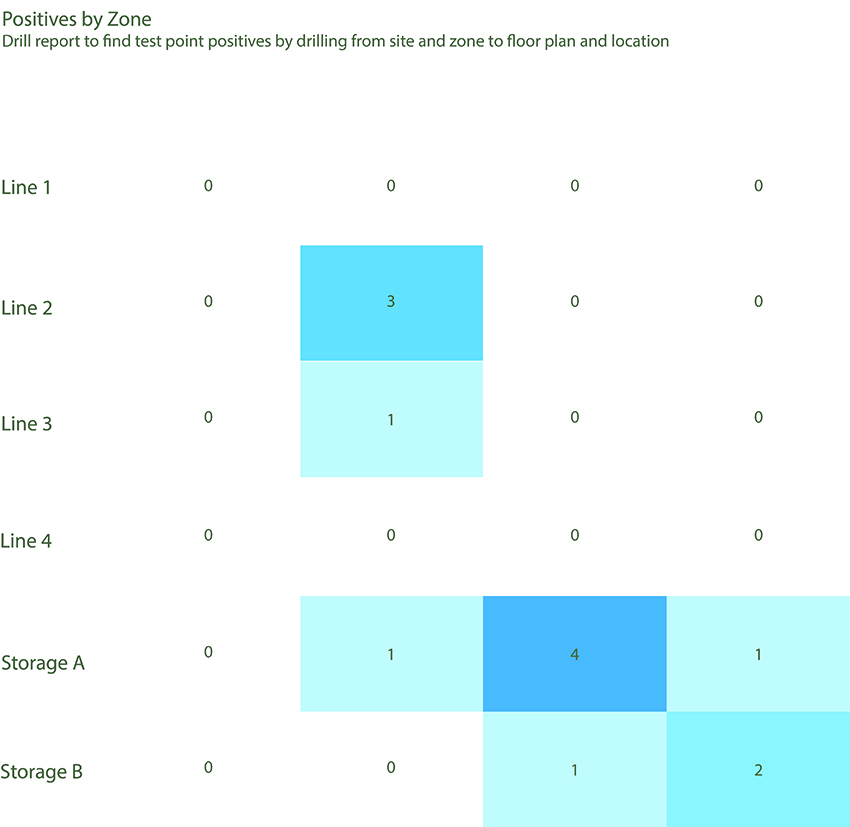

Inspectors will examine heating, refrigeration and cooling systems, facility processes, equipment, infrastructure, and beyond. Everything that uses electricity will be part of the audit, and analysts will be able to discern how much power each component is using. The statistics then inform action, driving a reduction in energy consumption. With this information, company analysts can also create a food manufacturing cost breakdown, which can be used to improve other areas of the business.

It’s easy to draw a line between regular energy audits and improved food safety, too. The ability to continuously monitor facility equipment performance means a lower chance of failure and more consistent quality. Keeping a digital eye on optimal performance means a reduced risk of one machine negatively impacting others if it begins performing suboptimally or erratically.

2. Upgraded Equipment

Energy conservation is as much about improving efficiencies as it is about using less electricity overall. While not always true, as a general rule, newer equipment tends to be much more economical at utilizing electricity.

Over time, technology has improved considerably to use less power, utilize resources more effectively and incorporate new methods for completing various actions, sometimes with significant performance boosts. In other words, new equipment can bring energy consumption down and will also improve productivity and output. Because it’s not cost-effective to replace equipment often, that’s precisely where audit information comes in handy.

The best practice would be to replace equipment before it malfunctions or breaks down, but also after it has declined in performance and efficiency. It would mean constantly analyzing equipment through real-time metrics and statistics.

Better production, more output, and fewer costs lead to greater profit, so it’s worth the investment.

More efficient and modern equipment typically features other upgraded components that impact performance and food safety as well, including updated materials, tighter tolerances, and improved microbial and viral resistance. Next-generation food prep and packaging stations that automate sanitation using ultraviolet (UV) light are examples.

3. Retooled Infrastructure

If the operation is located in an older building, it’s likely that much of the existing infrastructure and equipment is not just dated but also less efficient.

For example, traditional lighting sources use a lot more energy than LED or smart lighting solutions. HVAC systems may be non-existent or extremely outdated. Even facilities that are just a few years old may have obsolete elements.

This stretches far beyond the basics such as lighting to include power and utility components. A well-built and quality transformer setup will save money over time, for example. Replacing aging equipment can save food processing plants cash in the long run.

Investing in a transformer that doesn’t use a liquid cooling agent gives plant owners more options as they can be placed indoors or outdoors. They also have other business benefits, like longer lifecycles, lower fire risks, a more eco-friendly operation, and higher efficiency. A lower risk of fires, smoke intrusion and other destructive events also means greater security and peace of mind for delicate and perishable foods and food components.

Upgrading these components is more cost-effective than moving to a new location or building a whole new facility. It is often these kinds of incremental hardware and operational updates that can offer the best impact.

4. Better Refrigeration and Cooling

In 2019, the EIA reported that the commercial food sector used 154 billion kilowatt-hours of energy on cooling alone. That’s nearly 4% of the entire country’s annual energy usage. It isn’t just because cooling systems are running constantly year-round. It’s also because many companies refuse to upgrade to more efficient solutions.

Refrigeration is a massive energy hog. So how can it be improved? There are several ways:

- More efficient motors

- Reduced and more effective use of refrigeration space for walk-ins

- Smarter fans with variable frequency drives (VFDs)

- Renewable energy farms

- Intermittent absorption refrigeration

Food waste at the retail and consumer levels amounts to 30–40% of the United States’ total output and billions of tons per year. Better and more reliable refrigeration technology at every stage of the supply chain, including warehouses and vehicles, means less food wasted worldwide and greater security for products at rest and in transit.

5. Monitor, Automate and Notify

Through real-time monitoring and automated processes, managers and operations teams can take action to reduce consumption. For instance, let’s say an employee walks away from a piece of equipment and leaves it powered on. With traditional equipment, that machine would continue draining power and increasing costs.

With automated and smart equipment, a notification would be sent to the appropriate administrator, who can then send out an order to have the machine shut down. Moreover, this can all happen within an instant, and administrators can be off-site and notified remotely.

Even better, the process could be improved further by installing an IoT sensor that automatically turns off the hardware after an expiration period.

An energy dashboard, accessible via mobile platforms, would allow facility managers to keep an eye on resource consumption, general costs, and operations no matter where they are. Creating a unified and always-on system with automation is definitely possible with the help of modern technologies like the Internet of Things (IoT).

The cost of food supply chain recalls stands at 48 million illnesses and $55.5 billion per year in productivity losses, amelioration efforts and the rest of the fallout. As with the other points made here, an investment in higher-efficiency equipment with lower power requirements translates to dividends elsewhere.

More efficient and widely connected machines in the supply chain mean fewer opportunities for failure and pricey recalls. This also leads to ongoing cost savings, which begin on day one.

6. Educate Employees

A cultural response to energy reductions can also have a huge impact. By training and educating employees on the importance of energy conservation, companies can gain an edge. This could include steps as simple as turning off the lights when departing an unoccupied room, remembering to power down equipment, or discussing more effective techniques.

If and when people are armed with the correct knowledge, they can make more informed decisions. The idea is to build a culture around energy conservation, operational efficiencies, and smarter utilization. Make it a team-based practice so everyone holds themselves accountable and values the initiative.

Cultivating mindfulness in this area of the company’s culture translates elsewhere, too. Safeguarding against unsafe habits, incorrect equipment usage and improper handling techniques, and encouraging workspace sanitization, is everybody’s responsibility.

Whether it’s saving money on electricity for the company’s and planet’s sake or protecting the customer from product defects, ongoing education makes for a stronger culture and a more reliable product.

Make It Happen

The longer a manufacturer continues to operate without efficient solutions in place like the ones discussed in this column, the greater the energy consumption levels and the higher the expenses. It is beneficial to all to adopt some of these practices as soon as possible, and there’s no question that it will result in higher profits. In several ways, some less obvious than others, this efficiency transformation means safer products, employees and customers, too.

As energy prices continue to climb across all sectors and the impact on the environment mounts, it makes sense to reduce consumption, find smarter sources like renewable energy, and upgrade equipment, processes and operations accordingly.