It’s safe to say that 2015 has been one of the worst years in recent history when it comes to food contamination. Everyone from global food manufacturers to major restaurant chains and grocery stores perpetuated or experienced outbreaks of foodborne illnesses like E. coli, Listeria, Salmonella and Norovirus. From farm to fork, the food industry needs to evalutate and improve its processes to deliver the utmost health and safety to consumers.

With FSMA and tougher industry standards in place, there will be much more emphasis on preventative measures—especially for food manufacturers. FSMA establishes a legislative mandate to require comprehensive, prevention-based controls across the food supply to prevent or significantly minimize the likelihood of problems occurring.

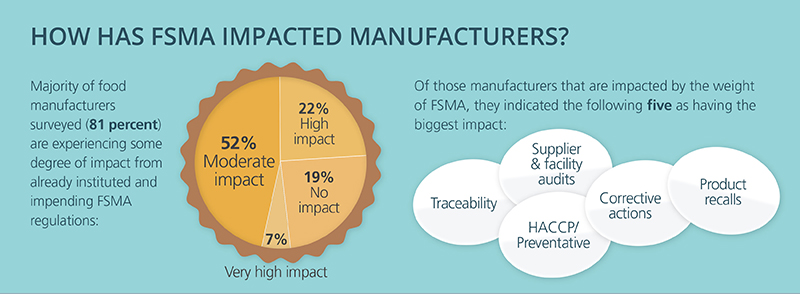

Even though most of the regulations affiliated with the FSMA have just gone into effect, or will go into effect in 2016, food manufacturers are already feeling the heat. A recent survey found that the majority (81%) of food manufacturers are experiencing some level of impact from current and impending regulations. Processes pertaining to traceability, supplier and facility audits, HACCP and product recalls are causing the most concern. While most food manufacturers support FSMA’s mission to put prevention at the forefront, the reality is that many aren’t equipped to handle growing compliance demands.

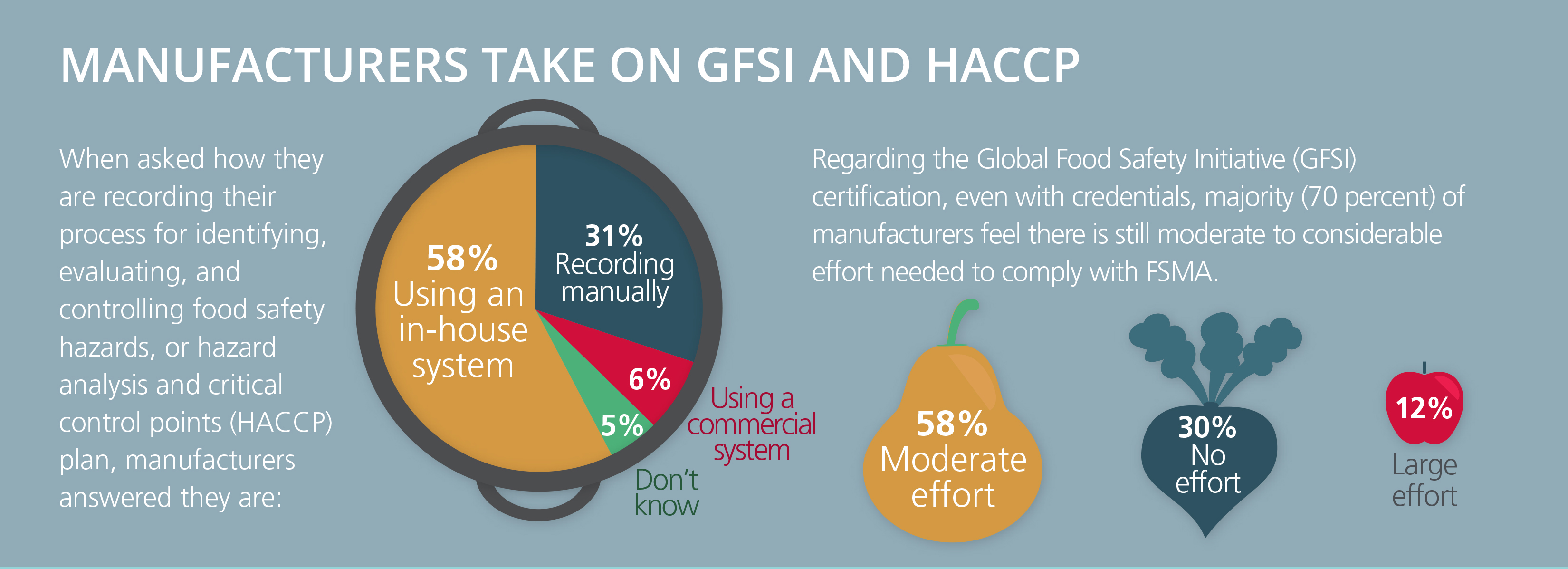

There are still a sizeable number of food manufacturers that manually record their processes for identifying, evaluating and controlling food safety hazards. In fact, more than 30% of food manufacturers document their HACCP plan in this manner.

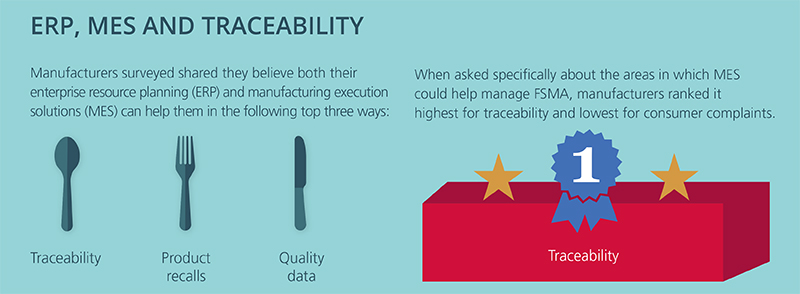

With FSMA, there isn’t any room for human error. Although technology with track and trace capabilities has been available long before FSMA came into play, obstacles such as complicated interfaces, lack of interoperability and resources deterred wide-spread adoption among food manufacturers. The tide is changing here. Advanced enterprise resource planning (ERP) solutions have built in track and trace functionality that is more intuitive and integrates seamlessly with vital manufacturing execution systems (MES).

Although the FDA does not have the legal authority to require companies to use computerized traceability solutions, implementing track and trace technology is one of the most effective measures a food manufacturer can take when it comes to FSMA compliance. It can help create a more systematic and reliable account throughout the lifecycle of a food product, and also establish preventative measures, including automated product checkpoints and quality tests throughout the supply chain. Ultimately, this gives food manufacturers the opportunity to identify and prevent issues before they become epidemics.

In addition to taking strong measures to prevent contamination, under FSMA the FDA now has authority to initiate mandatory recalls. Although mandatory recalls are anticipated to be rare, food manufacturers should use track and trace technology to make recall preparation routine. When used properly, these tools can pinpoint specifics about a product in real time, streamline quality reporting, and launch mock recalls.

Of course, technology is not only the vessel for improvement—to actually see change, food manufacturers need to take a critical look at their processes and make adjustments. Automating poor processes will only accelerate poor results, therefore approaching FSMA compliance and implementing track and trace technology requires time and strategy.

Ultimately, your company’s reputation is on the line as well as the safety of consumers. Dedicating necessary resources toward compliance planning and technology implementation is always well worth the investment. Many of the companies and suppliers that were in this year’s spotlight for contamination will look back on 2015 with regret because safety wasn’t at the forefront. Let’s learn from the hard lessons they provided and make 2016 the year that food manufacturers win back consumer trust and focus on quality.

Great article! I like the point you made about how ultimately your company’s reputation is on the line if they fail to follow the FSMA’s policies. As consumers become more interested in accountability and transparency from food companies, the importance of equipment for food safety, such as magnetic saparators and x-rays, goes up.