Having the ability to detect and identify contamination and adulteration in product is a top priority for companies, especially when working with foreign suppliers. In a discussion with Food Safety Tech, Craig S. Schwandt, Ph.D., director of industrial services at McCrone Associates, discusses how companies, especially those with limited resources, can use technologies to improve contamination detection to be ahead of the FSMA implementation curve.

Food Safety Tech: From your perspective, what key elements of FSMA will have a big impact on manufacturers and processors?

Craig Schwandt: For U.S. manufacturers, more and more of their ingredients are coming from foreign countries. [Companies] are responsible for reporting to FDA what measures they have taken to assure food safety in all aspects. Participating in the Foreign Supplier Verification Program will be critical to [their awareness of] whether their foreign suppliers are meeting those obligations. That critical element hasn’t been realized yet.

FST: Is navigating the foreign supplier relationship more of a challenge for smaller businesses versus larger companies?

Schwandt: Global companies have the resources to address contamination concerns and can monitor the processing that takes place in foreign countries. It’s the small companies that don’t have the financial resources to be present in foreign countries. There will be many more issues for them to address—are they really receiving product that they’re paying for? Is the testing that is being conducted in foreign countries really meeting the requirements.

FST: What steps can small companies take to ensure they have testing programs in place to meet requirements?

Schwandt: This ties in with the difference between testing and investigational analysis. Testing involves identification methods that are done to ascertain what is present—it might be an elemental concentration basis or an organic molecule basis—but they’re bulk analysis that determines whether the product is meeting the expected composition.

Then there might be components for which there are actionable levels, if the concentration exceeds actionable levels. But with bulk analysis testing methods, they only understand that they have a component in their product that exceeds an action level, and those methods don’t really specify where that component might be introduced into the product. This is where microscopy-based investigational analysis can assist smaller companies with understanding at what point the contaminant might have been introduced into the product. It can be isolated in individual particles, establishing a forensic pathway for stage of the process in which the contaminant might have been introduced.

FST: Can you expand on the technologies and methods that can be used to detect fraud or adulterated product?

Schwandt: In the case of intentional adulteration and fraud, current technologies include ultrahigh pressure liquid chromatography, liquid chromatography, and mass spectrometry, and the food industry is doing a great job of using them.

In the case of intentional adulteration or fraud, the level of adulteration has to be fairly high, otherwise there isn’t an economic incentive to adulterate it. A great example is with pomegranate juice—if you’re going to intentionally adulterate pomegranate juice with grape juice to cut it down, a fairly large percentage of the final juice will be grape juice in order to make that intentional adulteration process economically motivating. It’s not really so difficult to identify it with [current] technologies.

Where the technologies need to be improved is in instances in which there might be more unintentional adulteration or contamination at trace levels:

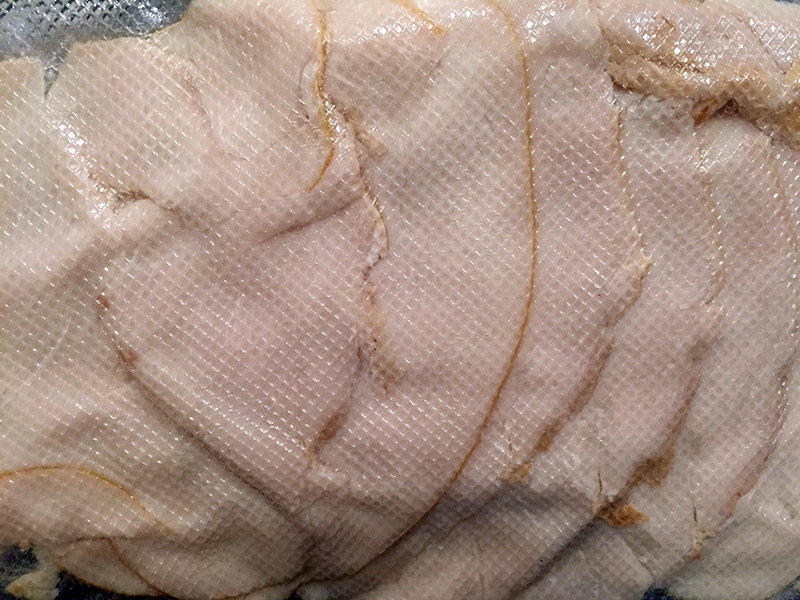

- When there are solid phase particulate contaminants, use of microscopy-based methods (which isn’t new technology) where you isolate the contaminant particles of interest; they occur at trace level. Because we isolate them from the matrix, we can analyze them and [detect] if there were metal particles from processing machinery; we can identify them to the alloy level and give clients a way to trace back to what part in the process stream those particles may have originated.

- Likewise, Liquid chromatography and mass spectrometry, especially for pesticide residue analysis, will be increasingly more valuable using the QuEChERS program FDA has outlined for quick, safe, reliable and easy analysis of trace contaminants in food products.

FST: What factors are contributing to under-use of microscopy-based methods?

Schwandt: I think the expensive–instrument vendors would like you believe it is as simple as pushing a button to receive your complete quantitative answer. In many cases, the instruments, even though they might be designed with the best intentions, actually do require expert chemists to use them for complete success. There’s a push on the part of instrument manufacturers to provide instrumentation that they sell as providing the complete answer. And there’s a willingness in the food industry to believe it would be as simple as putting a less-skilled person in front of the instrument to run the analysis, push the button, and get the answer, as opposed to hiring an analyst with a lot of expertise.

FST: What industry partnerships/collaborations are essential in testing and analysis?

Schwandt: The partnerships are productive in this area when they’re between production and quality assurance branches of companies and third-party laboratories that can offer niche solutions and third-party verification.