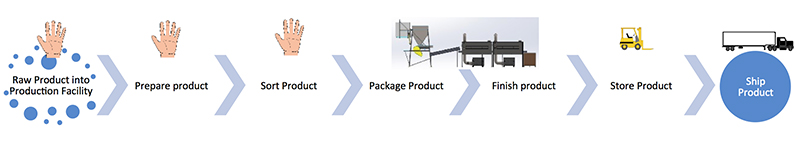

With an understanding of quality control, we prepare for pathogen-free production by reviewing operations and control measures. Review the plant process by looking for the opportune points of contamination concern that we use to ask, “What controls are available to mitigate risk?” This presents the opportunity to create control through disinfection. At this point, a fresh look at product quality and handling is demanded to gain control of the process deliverable. Let’s review the plant process again and now look at touch points of product throughout the process (see Figure 2).

Touch points drive the consideration of processing and the method of cleaning pre-production, during production, and post-production. For critical control mitigation, we will consider the disinfection method during production through the use and method of radiant ultraviolet (RUV), which utilizes the technology of ultraviolet as a surface, air, touch-point, and process control. UV is a light-emitting technology adopted by the FDA in 2000 as an approved technology that can be used for decontamination of food and food contact surfaces by killing or rendering pathogens unable to reproduce. It is considered an alternative to physical treatment such as a non-ionizing disinfection solution. This is a highly sought-after solution, as the treatment of UV does not produce undesirable by-products, which allow the solution, when produced as RUV, to directly expose product and process touch points without altering food quality, color, or general appearance.

Utilizing this technique, the product flows from raw to storage with critical control RUV disinfection from entry to exit. Measurement and control must work together to create pathogen critical control disinfection for process and product. Through the course of production, we look further in the process to understand the product touch points. This is typically reviewed through testing by swab or plate counts. Testing verifies a known; however, this is often not the case in production facilities. Testing becomes a measure of what should be rather than what is expected. Risk mitigation is critical to process and compliance, and test methods should be included as repeatable results of a working system. RUV as mitigation a process control measure provides critical touch point control of air quality to product, equipment surface to product, post-human handling to product, and pre-packing of product. RUV is the critical control of disinfection during the production process. How we control production touch points, measure for result and report those results are critical to operation and quality. RUV is the use of UV disinfection processing during the food process. With the use of RUV, the touch points of processing are controlled.

Excellent approach using UV technology as a preventive control. I concur, and now LED technology is being developed using specific light spectrum frequencies to target specific foodborne pathogens for dry sanitation methodologies vs. wet sanitation applications. Appreciate the new approach using UV light.