Validation

The decontamination was only deemed to be complete once all 14 sampling locations read the appropriate dosage for a 6-log sterilization level kill. After the gas was removed, the decontamination team entered to recover the biological indicators, while plant personnel entered to take swab samples throughout the production areas. Biological indicators were processed by dropping the spore strip into growth media and incubating it for 36 hours. If any spores were left viable on the spore strip they would multiply and cause the growth media to change color, offering a quick method of validating the process. After processing, all 60 biological indicators came back negative for growth, while the positive control biological indicator exhibited growth within 24 hours of incubation. Swab results taken by plant personnel all came back negative for Listeria monocytogenes as well. Production resumed within the facility 48 hours later Listeria free.

Preventive Decontamination

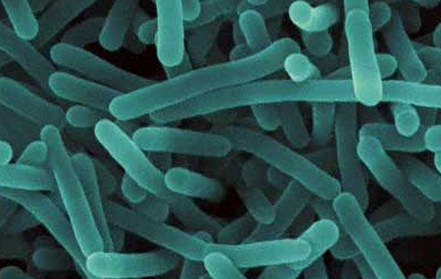

Once the facility was rid of its Listeria contamination and production resumed, facility supervisors put forth a plan to decontaminate the facility on an annual basis as a preventive measure. This was to be done in addition to their traditional sanitation program during a yearly shutdown event. As traditional sanitation methods have difficulties eliminating pathogens from hard-to-reach areas, they provide a reduction of pathogens more so than an elimination of pathogens in those crevices. Chlorine dioxide gas provides a complete decontamination due to its ability to penetrate into crevices further than pathogens can hide, sterilizing all surfaces within the facility.

The company performed a risk assessment by reviewing their environmental monitoring results to pinpoint the areas to be included within the preventive decontamination. The tank alley located separately from the production area was considered to be a lower risk and was not included in the scope of the yearly preventive decontamination. The entire production area was included to provide a baseline sterility level and reduce the risk of contamination. As pure chlorine dioxide gas does not leave a residue, it can safely be used on a routine basis to provide sterilization of food contact surfaces and production equipment.

The preventive decontamination project was successful in resetting the production area back to a sterile environment. Biological indicator and environmental swab results both came back negative for growth, validating the process’ efficacy. This instilled greater confidence within facility management that the facility would run cleaner and safer than ever before.

Conclusion

Responsive decontamination is hugely important, but preventive decontamination has evolved from being the future of contamination control to its present. Recurring contaminations often times are brought about by cracks and crevices providing pathogens a place to thrive and avoid being removed during traditional sanitation. In order to reach every crack and crevice in and around all equipment, a decontaminating agent such as chlorine dioxide gas, which is easily distributed throughout and penetrates into every crack, is required for successful decontamination. Failure to eliminate all pathogens will result in recontamination over time as surviving pathogens have time to multiply to large enough numbers where they can be transferred to other locations in the facility and cause a more widespread contamination. These recurring contaminations cost more money in the long run, especially if they are discovered by FDA and USDA inspectors. Chlorine dioxide gas has been proven to be a successful decontaminating agent capable of killing pathogens in areas that other sanitation methods fail to reach. In today’s food safety landscape, preventive decontamination is essential, and chlorine dioxide gas offers the process advantages to reduce the risk of contamination and recall.