IFSAC collected and analyzed previously collected data to assess if older programs, such as 21 CFR 118 production, storage and transportation of shell eggs, actually reduced the incidence of Salmonella enteritidis illnesses. This is a structure for the environmental testing of hen houses for this pathogen which, if found, requires the testing of the eggshells for the same pathogen. If the pathogen is found on the eggshells of a product destined for the processing market, a kill step can be performed to eliminate it and avert consumer illness. The review of this data proved that this program and other interventions have been effective in reducing illness caused by Salmonella enteritidis from eggs.

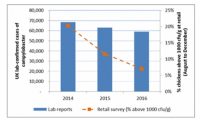

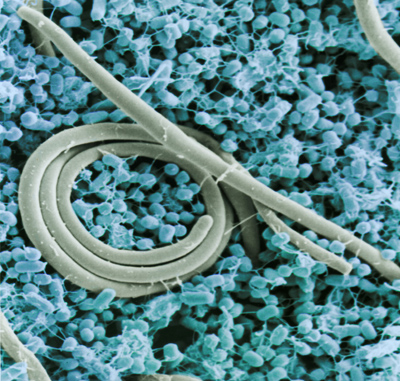

Data collection to reduce the incidence of foodborne illnesses is taking place in many locations. The Food Standards Agency (FSA) in the United Kingdom has been monitoring Campylobacter in chickens since 2014. FSA sampling was performed at the retail level. By sampling and testing, then working with the industry and retailers, the percentage of chickens testing positive for Campylobacter has been reduced from 78% in 2014 to 56% in 2016. The level of chicken with more than 1000 cfu/g of campylobacter reduced from 20% in 2014, to 7% in 2016. Additionally, by working with consumers to improve kitchen practices, the surveillance agencies have reported a 17% reduction in foodborne illness related to Campylobacter contamination (see Figure 1).1

The FSA will be changing the way it monitors Campylobacter levels on chicken so it can better focus on those processors that are not making significant improvements in their reduction of this pathogen.

Sampling and testing is just one of the many aspects of a good structured food safety plan. Process and program audits, training and other key elements are essential too, but sampling and testing is an area that is often neglected because of the fear of finding results that are out of compliance. This fear is not warranted. If the food safety plan is designed properly then these out of compliance results are used to perform continuous improvement in the food safety plan. Essentially, continuous improvement is necessary to become a major player in the industry, and this is how the most successful companies excel. Governments have shown that a structured plan that incorporates the correct sampling and testing will result in a reduction of foodborne pathogens. Although it is still essential that the materials be handled properly throughout the supply chain, it is also essential that consumers are trained to properly handle and/or cook these materials, as there is a risk involved with some raw ingredients. Foodborne pathogens are part of some products’ risk, and making a structured plan to reduce, and hopefully one day eliminate these pathogens, is an essential part of doing business.

Reference

- Food Standards Agency. (March 2017) “Latest figures reveal decline in cases of campylobacter”. Retrieved from https://www.food.gov.uk/news-updates/news/2017/16052/latest-figures-reveal-decline-in-cases-of-campylobacter

Very informative write up.